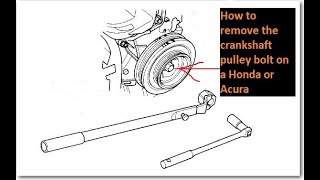

DIY: Honda / Acura: Crankshaft Bolt Removal - Tips & Tricks - Bundys Garage

Вставка

- Опубліковано 25 сер 2014

- How to remove that stuborn crankshaft pulley bolt on a Honda / Acura. I show you some tips and tricks to get this bolt free. We use chemical warfare as well as brute strength but in the end, fire and brimstone set this bolt free.

20 UA-cam Repair channels to watch in 2020: blog.feedspot.com/auto_repair...

The engine in the video is on a 2000 Honda Accord EX 2.3L F23, very similar to the 2.2L F22. Please note, the rotation of the engine is counter-clockwise. The crankshaft pulley bolt has a standard thread, rightey tightey, leftey loosey.

Vehicle List for F22 / F23 Honda Acura:

2.3L F23

1997 Acura CL 2.3L

1998 Acura CL 2.3L

1999 Acura CL 2.3L

1994 Honda Accord 2.3L

1995 Honda Accord 2.3L

1996 Honda Accord 2.3L

1997 Honda Accord 2.3L

1998 Honda Accord 2.3L

1999 Honda Accord 2.3L

2000 Honda Accord 2.3L

2001 Honda Accord 2.3L

2002 Honda Accord 2.3L

1998 Honda Odyssey 2.3L

1998 Isuzu Oasis 2.3L

1999 Isuzu Oasis 2.3L

2.2L F22 Engine

1990 Honda Accord 2.2L

1991 Honda Accord 2.2L

1992 Honda Accord 2.2L

1993 Honda Accord 2.2L

1994 Honda Accord 2.2L

1995 Honda Accord 2.2L

1996 Honda Accord 2.2L

1997 Honda Accord 2.2L

1998 Honda Accord 2.2L

1995 Honda Odyssey 2.2L

1996 Honda Odyssey 2.2L

1997 Honda Odyssey 2.2L

1992 Honda Prelude 2.2L

1993 Honda Prelude 2.2L

1994 Honda Prelude 2.2L

1995 Honda Prelude 2.2L

1996 Honda Prelude 2.2L

1996 Isuzu Oasis 2.2L

1997 Isuzu Oasis 2.2L

Links:

50mm Crankshaft Pulley Tool (To Hold Crankshaft Pulley):

www.amazon.com/Powerbuilt-6487...

Brians Mobile Crankshaft video:

• LIVE demonstration of ...

Another video by Briansmobile1 on the subject:

• How to remove that stu...

Music by Randall Keny

Copyright © 2014

All Rights Reserved

Bundys Garage

DISCLAIMER - DISCLAIMER - DISCLAIMER

Due to factors beyond the control of BundysGarage, it cannot guarantee against unauthorized modifications of this information, or improper use of this information. BundysGarage assumes no liability for property damage or injury incurred as a result of any of the information contained in this video. BundysGarage recommends safe practices when working with power tools, automotive lifts, lifting tools, jack stands, electrical equipment, blunt instruments, chemicals, lubricants, or any other tools or equipment seen or implied in this video. Due to factors beyond the control of BundysGarage, no information contained in this video shall create any express or implied warranty or guarantee of any particular result. Any injury, damage or loss that may result from improper use of these tools, equipment, or the information contained in this video is the sole responsibility of the user and not BundysGarage. - Авто та транспорт

Tried bump start to get crank bolt out ya right it stop the motor from turning over had the tool reckamended tool on the crank to holed it from turning use the long snapon braker bar 3 ton floor jack and the weight of the car to brake it free had the front of the car lifted before it loosened that was the only thing that worked had a 6ft cheater bar on the end of one braker bar and it snap it 3 impact sockets 2 impact exstentions the toughest thing i ever had to take off and i use to take rust lugs off bud wheels 45 ft trailors easer than that bolt

Right! All these guys in the comments stating to just bump start the engine and it will pop right off. Well your the proof, does not always work and have seen bolts stripped as well as snap off from that technique. Also not to mention the stress put on internal components when you try and do that. Glad you we’re able to get it off!

I think I got the gist of this comment. But good Lord, did it make my head hurt trying to figure out what in the world you were saying.That was a mouthful for one whole sentence.

What’s so hard to understand?

@@bundysgarage it wasn't your response that was hard to read. It was more of just a little poking fun at the run on sentence of the original comment. Just poking fun, not trying to be a complete ass, just having a little fun.

That's risking damage to the starter, and or flexplate. I have had luck with a manual transmission putting it in 5th gear have someone stand on the brakes while using a 4-foot steel pipe to leverage it after heating the bolt with map-gas torch.

This is a real life video. Takes a lot of time and effort to accomplish something like that, unlike other videos that show just bs how easy is to remove a crank bolt.

All my years with Honda. I know the struggle lol. The solution I found that works for me is with a impact along with a weighted 19 mm impact. Not just a impact socket but a weighted one.

Even then, with a neglected car the pulley won't come off. Even with the weighted socket, heat, and oil. The leverage is the only way

Yep. The physics shows that the force applied by a heavy duty impact gun (2000mn+) with weighted socket, far exceeds the force able to be applied by a breaker bar, even when the bar is being lifted by a jack.

I'm trying to break the one on my 2010 Acura TL and I bought one of those awhile back and totally forgot! I'm going to get it out of my roller, now!

Ive made a custom one for my work

The last time we had to loosen a crankshaft bolt, it took three of us with a massive breaker bar and it still didn't loosen off 😂 it took an hour in a Honda garage so you're doing alright there 😂

The spot you’re trying to heat is the washer according to the other video. Keeping the special tool on there allows you to back the torch off and guide the heat more directly at the washer. Thanks for the video. Now I gotta get to the next five hours of labor.

Perfect. Thanks for this. The use of the jackstand to support the extension was key to breaking it free. I just slid a 3 foot pipe over my breaker bar and voila. Thanks again!

Just did this in a 06 CR-V. Have a IR 3/4 @175 shop air. Has never failed til now. This worked well.

I HAVE DONE SO MANY HONDA AND ACURA BOLTS I NEVER SEE SOMEONE STRUGGLES THIS MUCH. WE HAVE THE TOOLS AT THE DEALERSHIP.

MY SOLUTION IS SIMPLE. USE THE 19MM SOCKET AND LONG BREAJER BAR. LOCK UP THE BAR AGAINST THE LOWER CONTROL AND CRANK THE ENGINE. SNAP RIGHT OUT. ALWAYS WORK FOR ME

I use acetone/ATF (50/50 mix) and apply it for 1-3 times daily x 3-5 days. I know other people probably won't have the time to do this, but it does work for me. I also replace the crank bolt regardless. I've seen microscopic scans where the threads have tears so I replace it. Also, anti-seize is your friend.

THE TORCH DID IT! thank you so much! we would have never gotten it off without the torch! im overwhelmed with the satisfaction of what sounded like a gunshot in my engine compartment.

+Anthony Moore yeah that's a good feeling when it breaks loose and you can move forward with the job! Glad to hear it helped you out. Thanks for watching, that's why I made these videos to help my peeps out!

The heat breaks down the locktight 150 degrees is what it takes so you have to heat the bolt awhile to reach this

Thank you so much for sharing this video!!! We had to do this and we were able to get it off first try after heating it!! It broke loose as soon as yours did on the video!!! Thanks again!!!

Hey man I followed your procedure and it worked perfect on a 2008 accord 2.4. I was sweating bullets when my IR wouldn't budge it. Spray + heat + leverage did the trick. Thanks for sharing!

+MAY03LT no problem, glad it helped you out. It makes me laugh when others on UA-cam show the bolt coming off with no effort at all. Those bolts are typically bears!

🙌No Prob Bro 👌

Thanks for this. I shattered a socket and extension. After using the same little torch it finally broke free after literally standing on the breaker bar :)

I broke a socket (SK!) too. Time for the heat. I have a new crank seal already to replace.

What a hell with this bolt!

Finally you got it.

Best regards.

Thanks Bundy, I used your jack stand method along with my 3' thick-wall pipe for an extension to my breaker bar. Bounced it once or twice with my 315 pound ass and BAM, it was loose.

2002 Accord SE 315,000 miles.

I would of done that plus penetrate oil no torch

Great Video. Try the same job myself after watching the video. I try the impact gun several times with no luck. Heat the washer with the propane gas torch several time and try the impact gun again, still stuck. Then I try the break a bar with a long pipe. It still stuck. Then I went back to heat the washer with the propane gas torch for 5 minutes and try the break the bar again. Finally it break free. Thanks for the video.

They can be one tough SOB. All the air and cordless impacts will never take the bolt off sometimes. Sometimes you just need brute force.

3/4 drive stuff was the ticket for me. No heat. I used the jackstand idea, that was helpful, thanks.

What did you use a 3/4 air impact?

No, extension and breaker bar with pipe.

Next time, a trip to home depot will save you time I bought 7 ft of black pipe from the plumbing isle, added it to the breaker bar and applied 260 pounds of sexy to it, I still had to stand on the pipe but it broke loose by the second try. only took a few minutes. Still a good video, it illustrates all the fun times to be had in ones garage or on the drive way 😆👍

Finally... A video that the mechanic shows how much of a pain in the ass it really is instead of making it look as if it ain't shitt😆😆😆

No kidding. I hate all those videos where they show it being all easy. This bolt can bring a grown man to tears!

@@bundysgarage ever shear off? Wouldn't heat take the temper out of the bolt?

Cody Rogers it ain't shitt if you know what you're doing. Weekend Warriors trying to work on cars. Just stick to being a gasoline jockey leave the technical stuff to the pros.

Mechanics have proper tools. No profesional mechanic would of attempted this without an impact. It’s just stupid to do it other wise. Especially if they’re trying to beat the clock.

@@bundysgarage I'm in tears as we speak. I'm doing this right now for the past 3 days. FU*kkkkkk that bolt!!!!

That's the way I pull out a lot of bolts thank you real good video

Super helpful, nobody really explains using breaker bars for this

I broke the head off the crank bolt of a civic using a breaker bar, a jack stand, and standing on it!! Took a lot of drilling to get the remnants out.

Do you have any pictures of that. Guys say to use the starter method but I have seen the bolts strip. Haven’t seen the bolt snap yet though.

BundysGarage I attempted that job about 17 years ago lol. I did finish it though. New belt and water pump and tensioner. Car finally went to the junk yard about a year ago 😬.

Damn WOW!!!!! You had me on the edge of my seat😱 and you look like a pretty strong dude and that steel was twisting

I just got a milwaukee cordless impact. Next time I do this it will come right off. 1400 nut busting torque. Last time I had to use the honda tool to hold the crank, a socket, an extension, a jackstand, a breaker bar, a pipe on the breaker bar and two people pulling on the pipe. I stood on the pipe and that still wasn't enough, both me and my 14 year old 5 foot 9 inch son had to put everything we had on the 3 foot pipe on the 2 foot breaker bar to break it loose. It had to be 1000 ft. pounds, every bit of it. The good news is the tectron breaker bar flexed but didn't break. I taped the swivel because I expected it to explode. Tectron makes some nice tools for the money.

U DA MAN !!!

Have lots of PB Blaster.

Going out now to buy 2-24" breaker bars

And a 1/2" drive 20" extension .

March 27 2015. GURNEE IL.

🤞I really hope the heat works my uncle has been at it for two days now and we just came across your video , I refuse to pay 900 for labor alone 😕 wish us luck !!!!

do you have an engine oil leak now down around this area...?

(oil filter spool, oil pump seals, crank seal)

👍

You got there in the end !. Good video 👍🏻

I was struggling with mine yesterday and after watching your video, I used the jack stand method as well as some heat with my torch for like a minute as you suggested. Used a 1/2' drive socket with a 12" extension on a breaker bar and the bolt came off easily after that.

Unfortunately, I broke off one of my Snap-on 3/8" breaker bars. That's all I had at the moment...:(... Definitely not a job for 3/8" drive tools.

The seal behind the pulley was leaking oil and mannnnn, that pulley just sprays the oil everywhere and makes a mess!

Anyway, Thank you for the great suggestions and also for detailing the torque specs when putting the bolt back. That was great!!!!!!. I'll be subscribing for sure. Love your real life videos and not all these fancy schmancy videos I watch with high end expensive ass tools you need for regular normal jobs.

I got so exhausted watching this guy.

It's not for the weak of heart.

Hahahaha😂😂😂

Just hold your breath and tighten your cheeks, don't let any air out, lol

The heat was not about removing rust...It was about exspansion due to heat of the area around the nut bolt..thus, helps make it possible to unscrew the bolt..

it was not about either. Honda has a serious thread lock tite added that the heat helps break up.

@@nonamemeable uhmm no lol I've removed DOZENS of factory tight Honda crank bolts with hardly a problem. Yeah some were harder to remove than others but the most difficult were the bolts that a prior mechanic removed then installed with a AIR HAMMER. That mixed with hard driving, bad road conditions and environment and over heating motor literally seizes the bolt inside the threads.

Whenever I have to remove this bolt I keep buying something to help me. This time I bought a 1400 ft/lb breakaway impact and a lisle 19mm heavy weighted socket. Used heat, PB blaster, and the new tools for about 20 minutes off and on.....nothing. Had to revert back to this method...old reliable. It's such a pain but it works. Recommend a 3/4" or 1" drive setup. Nice vid!

I don't own a Honda but was looking at some other repairs and Honda remained the subject. It is a tough car to work on But the videos are interesting and whether you own a Honda or not there is an education here. Impact wrench is looking good about now.

I had to replaced that pulley on my Acura TL 2008 a year ago. Watch bunch of videos people spending two days trying to loosen that bolt. Some "smart" expert suggested using starter for the job. I trusted that silly suggestion and my old starter went in smoke. Finally I decided to get a real tools for the job. Ordered 1/2" to 3/4" socket adapter on Amazon and got myself set of 12" 3/4 drive extension and 3/4" retched drive from Harbor Freight Tools. Spent probably $50. Assembled everything like in this video and used cheater bar from hydraulic jack. With 3/4" drive and extension there is no springing action at all. Stepped with my foot on cheater bar and bolt came loose in 20 sec. Whole removal was about 5 min. No heating, no spraying "snake oil". Why people putting those videos and wasting time on non existing problem. If you want to work on cars, you should first get correct tolls for the job. Many years ago a broke several 1/2" ratchets removing 36mm nut for the axle. Lesson learned....

Congratulations 🎉🎈🎊🍾 dude now is downhill for you there you had to break a sweat 😓

Hi, does the manual honda accord lx 1994 engine need the powerbuilt 648796 pulley like the speacial tool you used for removing the nut? Thanks.

had this with a corsa only way was impact wrench well done mate

Okay so using the jack and an extension to get the breaker bar past the fender is genius. This will allow me to get an extension on my breaker bar. I have the same issue on my Toyota that I have been working on for a day and a half and have yet to get it off. I used a floor jack on the breaker bar and still would not come off. I'm going out in the garage right now to try this method. I'm trying not to use heat for fear of messing up the crankshaft seal. did you have any issues with that? Thanks for the video. I'll let you know if it worked.

If you like hard work this is the way to go, if you like the easy route get the Lisle 77080 socket and a good IR impact!

dawnpatrol20 some people just like to get worked up and hurt for no reason🤣🤣🤣

Thanks for the tip. I read the reviews for this socket on Amazon and I'm sold! Everyone says the same thing you're saying. It seems like the extra $25 is well worth the saved effort. I just ordered it and will do the job as soon as it arrives.

That socket is good and has come in handy for me as well but be warned it does not work all the time.

@@bundysgarage I appreciate the effort you put into this video. It helps to know what you're about to get into. I'm about to pull a crankshaft pulley from a donor motor and put it into my own engine so I have to do this twice. Even if that socket helps me one of those 2 times it will be worth it. And if that doesn't work then its torch time!

@@bundysgarage It only works with a powerful impact. One with 1000+ break away torque. IR 7150 is the one I am using. Took me 3 tries with full battery.

when you tighten it back do you have to but glue again or just screw it on real tight?

I just did one of these with the identical setup of breaker bars, a special tool, and a jack stand that was tall enough. I also sprayed some lithium grease on top of the jack stand where the breaker bar and used a five-foot cheater pipe!

PITA sometimes! I stepped up from a 1/2 inch breaker bar and socket to 3/4 breaker bar and socket.

Yes some time this bolt and axle nut make a big problem but first I m locked flywheel with screwdriver in gear box hole for open this bolt thank you for sharing

Thanks for the video , I have a important question ? How do you troubleshoot a crankshaft pulley that is not aligned with all pulleys on a 2014 Honda Civic ex 1.8

They make a solid oversized socket that when paired with a decent 1/2 impact makes short work of this. I used it yesterday on my cousins v6 accord

Honda crank bolts used to be my nightmare. Now, I use a Milwaukee 2767 with the Lisle weighted socket and have never had a problem since. Now, Milwaukee has a new 2967 with even more torque. So, the old extension and jack stand routine is a thing of the past for me. No muss, no fuss. Quick, easy, and safe. Plus, as a bonus, you don't need to hold the crankshaft in place with the specialty tool. The cost of the tool will pay for itself in frustration savings for sure.

Hey man alot of people don't have $400+ for an impact 🔫 so the video was very helpful for those who cannot afford it thank for the video dude. and for those who did it with your daddy's , daddy forgot to tell you that honda crank pulley spins counter clockwise😳 thats why honda has that special tool😳 so do ur homework before you judge ding dong😂😂

The fuck it does! Don't post shit you know nothing about it causes people problems. The crank spins clockwise and the bolt is not reverse thread.

First I want to say, great video! I just want to help those in the same waters and add to this video.

7-29-19 Broke a craftsman chrome socket. 3/4

7-30-19 Harbor FreightTools 1/2 Black Impact Deep Socket 19m $3.99

1/2 Drive Impact Extension Bar Set - 9_1/4, 4_1/4, 2_1/2, 1_3/4 $9.99

I know the less extensions, the better. But I had to use 4 bars to bring me just enough out of the fender.

I sprayed Zep45 penetrating lubricant spray. Let it soak for 20 minutes. Thanks to this vid.

First attempt, I started dry, between 9, and 10 o’ clock. Touched the ground, nothing 😭

Second attempt, after 20 min. with Zep45. I went all the way to the top at 12 o’ clock. Broke loose between 7, and 8.

Used a 2” galvanized fence pole, 5’ feet long.

I weigh about 135lbs, 💪 no heat 🔥 no sweat!

Just BOMBass lubricant!!

That beyotch popped like I broke something 😂

Respectfully,

Thanks again brotha.

Good luck y’all, Get her done!!!

For me it was the torch that did it. Could have saved some grief if I'd used it sooner but... fire.

Thank you man I am on this situation right now just watched the video

I just bought a Lisle thick wall socket #77080 and it took it right off

Glad it worked for you. Sometimes it doesn’t.

Troche worked perfectly took me some time but got it out thanks

Tnx for posting ur video removing crankshaft bolt it is very educational, i have a question mine has a honda city automatic transmission model 1996 the timing belt was cut off we have to get these crankshaft bolt out with 17mm sucket where shoud we turn to lossen the bolt clockwise or counterclock wise? Tnx you for replying to my question

Hi, quick question 🙋♂️. I have a 98 CRV. Do you know what kind of screw is needed for the harmonic balancer? PLEASE AND THANK YOU

Milwaukee medium impact impact gun + high mass honda crank bolt socket and 0 extensions should work better no?

I recommend purchasing a Lisle 77080 19 mm Harmonic Balancer Socket for Honda crank bolt. This socket is all I use to take off the crank bolts on Hondas and Acuras. I use a 1/2 impact gun . The socket is very thick and heavy and that contribute to ease of the bolt removal.

First, the immovable crank pulley bolt. When he brought out the ginormous wristwatch to set the timer, I thought that this was a Mission Impossible episode

It should be called Mission Impossible trying to get the crankshaft pulley bolt out on some of these Honda’s and Acura’s.

@@bundysgarage Yeah bud I have a 98 Acura EL and I'm anticipating having to do this which is why I'm watching all these related videos. The big downside is the amount of work required if the root cause is water pump failure.

I have never been able to remove them without heating them with my acetylene torch. and a good impact wrench. if you don't have an impact gun you can use a sledge hammer and hit the end of the breaker bar to create the impact force to break it loose, but without heat I don't see it happening. unless you got a powerful impact gun. there is also a special socket for this, which makes it possible for an avarage impact gun to remove this bolt.

Your Awesome Brother !!!

GOD BLESS YOU ABUNDANTLY !!!

"aBUNDYantly !" (rimshot!)

how do i align it so i can insert the woodruff key. i can get it to go onside it onky goes halfway

Heat always works the best.

What about an impact?

I put my hands in front of my face to shield my eyes and teeth when I was that first extension do the twist. Get that big-assed 1/2 inch impact extension on there, or even bigger if needed. Even use no extension, but I see why he did what he did too. Nice use of the jack stand.

Stay gold.

+dnl machine stay frosty DNL

I broke 3 1/2 inch extensions

Hey how many times did u hit ur self trying to remove that thing because Im still struggling with it since yesterday

Good stuff, thanks man!

you have saved the day hope this works just as well for me

Your 80% there once you break it loose. Hardest part of the whole job.

Good job my friend!

questions? so can i buy it a set of those especial sockets?

or just one for the crankshaft pulleys?

thank you,

what's the name again for t6hose sockts?

thank you very much.

Its a Honda crank bolt socket (50 mm). You can find on EBay (about $20 U.S.). The other socket was a 19 mm

What is the first tool you put on there because this is my struggle right now on 05 Acura mdx ???

I'm 5 years late,but did you need a puller to pull the pulley off after you took the bolt off,or did the pulley come out by hand?

Excellent video. Notice how the 1/2" extension and head of the breaker bar twist and flex. If you do this often it may be worth investing in 3/4" diameter tools.

Yeah I know, at one point I thought the bar was going to snap in half. Check out this video on a Honda crankshaft pulley bolt socket: ua-cam.com/video/fn_cord6IA4/v-deo.html

+BundysGarage If you tried to properly remove the bolt using the right tools the right way, removing the Honda bolt would be a non-issue. I have never had a Honda balancer bolt that didn't come right out with ease. Losing the LONG extension would be a good start too. LONG extensions allow flexing to occur. Back to the basics! :O)

Gary Buffington yeah extension is eating all the torque. Its like you tryong to take off the bolt with a cooked noodle

@@garybuffington6021 you can use a long extension no problem, it's just gonna be real sketchy in 1/2 drive to get that torque. Move to 3/4 you can get that torque without fearing its gonna snap in your face. Without an extension you can't get more than a 20in or so breaker bar in there.

Correct. 1/2” has too much flex. I used 3/4” short extension 4ft lever. All good

I used the torch and a 12 point socket. The 6 point wanted to round the bolt off. Like some suggested I used the pipe handle from my big floor jack

Muy bien gracias por tomar se el tiempo para mostrar como trabajar

Master Bundy. Hugs forma Brazil!! Its a pleasure tô watch your vídeos and learn more and more. One question. Is the Honda accord V6 2004 ex an interference or noninterference engine in case my belt breaks?

I used the starter 😁👍

Works great

@ 8:35 is a good feeling when that bolt loose.

Good video. Sometimes giving the breaker bar or cheater pipe a few hard smacks with a mini sledge while you're pulling on it can make the difference.

I’ve got the beans to get the bolt out. The video I need is how to get it tightened back to the Honda spec of 47# + 60°, while sitting on jack stands. Honda is quite specific about not using an impact to tighten it.

Yup, looks like fun...

I'm going through the same situation haven't tried torch yet don't want to crank it over but now I know thanks to this video I'm not crazy.

Gonna try this in 2 weeks (2767 Milwaukee, Lisle weighted socket, propane torch, Kroil silicone in my arsenal)

@karan4425 start spraying the Kroil now on it!

Hi, quick question! I have a 1998 Honda CRV and I was wondering what size bolt I will need to replace harmonic balancer. Please help ASAP! Thanks 🙏🏽

Go to hondapartsunlimited.com, you can find the actual bolt size there.

" Did I get it?!"😆😳☺ Good video

I have to replace my girlfriend's harmonic balancer on her 09 Honda civic si. Watching your video really has me thinking hard, I hope is not as hard as yours.

Good job

Thank you for the video. I removed woodruff key and now I can’t put it back in, it is hard

Does everyone who does this first set the timing to 1?if doing the timing belt?

fighting one right now. For fun go find a 2006 Ford Expo. and try to take the lower rear strut bolt out. 331 flbs. 30 inch bar with jack handle added and me standing on it. I weigh in at 240lbs.

Job well done 👍

How long is the extension? The struggle is real. Great video, btw.

I have a F23 my pulley the same one,mine looks loose or warped,is it plastic,or does it just look like black plastic,I think my father inlaw,jacked the car up with it,or something happen,I noticed it,a week ago changing alternator

Good job brother

Take all the extensions and put the breaker on the socket and pull from above the engine.

wonder what the next move would be if you broke the bolt in the threaded hole....

I love most of bundy's video, but if you use torch to the crank bolt, crank seal may get damage.

Thanks but to let you know adding heat to the bolt is not going to hurt/damage/compromise the seal in anyway.

Agreed. By the time the bolt reaches proper temp, the seal will still be pretty cold. You gotta remember the bolt would have to transfer all that heat through the balancer and the crank snout. That's a lot of thick metal for the heat to move through

Those crankshaft bolts can be a real bear to get loose. I use a trick my dad taught me. Most of the time you can brace your socket against a frame member or similar strong support then just give the starter a quick hit. It breaks them every time, with no sweat.

+Morpheous58 What do you do, if you round-off the crankshaft pulley bolt?

+Morpheous58 Starter bump! Absolutely the best way to do it.

Morpheous58 doesn't work in this situation. this motor turn ccw so you'd just end up breaking something.

if its the orig belt(never been off before ~ start trick doesnt work, its just too frikin tight lol

civic motors are counter clockwise that dont work

No bueno my friend.

I thought it was going to be a 3 - 4 hr water pump job now I will have to work Sunday.

It can be a real PITA!

Mine required a trip to a friend's shop and the use of a 3/4" air impact. It was stuck like the one in your example!

Check this one out: ua-cam.com/video/XekOwTBj17w/v-deo.html

bundys hey what do i do on an 94 civic dx crank bolt with no holder are just has those 2 circes for a special tool im guessing any ideas ?

it dosent have the holder area ya know i have the tool but there is no spot for the holder tool

The extensions on the 19mm act as a spring reducing the torque applied on the breaker bar

D Esco yup, basically like a torsion bar suspension

i was thinking the same thing.

If you use an extension, it has to be hardened steel extension, low torsion, even then its almost impossible.

I too ran into the "infamous" super-hyper-tight crankshaft bolt on an Acura integra, never did get it off.

Has anyone tried a Torque multipler? There are torque multipliers on the market that can output 4275 ft lbs.....truckers use them all the time to take off stuck lugnuts on tires, with little effort.

Look up torque multipliers on UA-cam and you'll find them boys remove high torque, over tightened, rusted up, stuck lugnuts with minimal effort.

Thanks a million... 4 days of pure frustration. Me vs the Bolt from hell ended after 1 minute of the torch... Cheers!

Hell Yeah!

You have got the jackstand to allow it to support the extension so you should always press down on the breaker bar not upwards or sideways !!

r

I got mine off with a 3/4 Snapon impact

I think you want to torch the washer cuz that's where most of the forces being held. Also have your Breaker Bar lower down so you could just step on it. You can get a lot more pressure that way.

yep or buy a $80 Bauer impact wrench on sale and never look back 😁

Impacts don’t always work on these bolts.