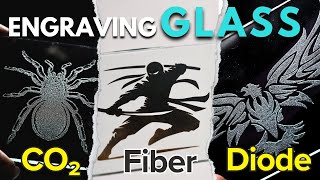

Engraving Glass on a C02 Laser? I Don't Think So. Thunder Laser BOLT. 044 4K

Вставка

- Опубліковано 4 жов 2024

- Many of you have asked for my Engrave Settings for Glass. I'll provide them today however, although you can engrave glass with a C02 laser, the results may not meet your expectations. I'll walk you through my findings and settings. If you have better settings or have a method which you believe produces better results, leave them in the comments for us all to test out. Cheers!

#engraving #glass #bolt

Laser NUG

Utilities /Equipment List:

Thunder Laser BOLT RF C02 Laser www.thunderlas...

Lightburn Software www.lightburns...

MAC OS - Latest Version www.apple.ca

PiBurn "BOLT" GRIP Rotary www.lensdigita...

Thunder BOLT 2.5" Focus Lens Kit www.thunderlas...

Thunder BOLT 4.0" Focus Lens Kit www.thunderlas...

ROKO Twister Tray computercreati...

Honeycomb Lay Flat Pins for BOLT www.etsy.com/l...

IMPORTANT: Lasers often project images that resemble strobe-type effects. If you suffer from health conditions such as, but not limited to, Epilepsy or Light Sensitivity, please do NOT watch these videos.

IMPORTANT: I am a brand new Laser User. These videos are provided based on my continuing learning experience. I am not an expert. These videos reflect my learning experience and are not provided as expert tutorials or expert opinion. Consult your manufacturer and/or manuals for your laser-specific requirements. These videos are intended for entertainment purposes only and are NOT provided as instructional content.

Hello for Iowa, from a fellow Bolt Laser and Kubota tractor owner- watch both your channels! I have ended up having the most success with damp typing paper stuck tight on the glass, 276 DPI, speed 300, power 80/75 Jarvis, an image graphic Gamma .8. the damp paper allows me to crank the power so I got a more solid white and still no edge chipping. I was experience the edge chipping on the lead in side of the graphic before stumbling on to the paper recommendation and that did the trick.

Good morning and thanks for watching both channels! Appreciate the great advice - Have a wonderful holiday weekend!

Thanks for the video.

I have use the transparent vinyl masking tape from JDS. I apply this to my glass piece and laser engrave the design. I then mask the remainder of my workpiece with the wide blue tape from JDSt leaving no bare glass. Then use a sandblast operation to ablate the laser engraved areas. Hold the blast nozzle about an 8” distance from the piece and do some passes. Don’t hold the blast nozzle in one position. Scan over your design with it. You’ll be able to see the light reflection from the laser fractured surface turn to a uniform frosted look. The red mask must be firmly applied for it to hold up well with small text or finely detailed designs. When done brush off the sand clinging to the surface. Remove the masking tapes under running water.

Of course this entails the added expenses of a blast cabinet, sand blaster, the two types of masking tape, and a suitable wash area. If you unmask dry there’s a strong chance of scratching the workpiece.

Hey good day and thanks very much for the info - greatly appreciated and informative. Have a great Independance Day!

I ran some tests on pint, rocks, and stemless wine glasses. I get a pretty smooth engrave without chipping at 250 sp and 20 power, I then tested 250 sp at 50 power and that was just a little brighter engrave with no chipping. Also I use a very fine micro mesh sanding pad that I found on Amazon. They range from 1500 to 12,000 grit, not sure which one I use but its probably in the middle of that range. I found that more power does cause chipping. Also this is with the stock lens and coming from an Omtech laser, I run air on everything.

Thanks very much Randy!

With my 100w CO2 I use a product called Blaze Orange for glass. Works really well. It’s a little pricey. When applied it puts a thin barrier between the glass and lazer. I get really nice engraving with it.

Thanks - are you referring to the spray paint used for safety cones etc? Made by Perfomix? LOL. I think I found it - it is a film called Blazer Orange. :)) Thanks again!

Yes that’s it. I purchase it through JDS. Works great. If you would like a sample I can send you a piece of it to try if you like. Also, what I found out cheaper the glass, the better it engraves.

Have you tried spaying a dark coat of chalk removable paint before you engrave, Sir

Love your Channel and knowledge of using a laser.

Great information Gord and we know you'll keep on till you get where you're happy with it. I received my Old Dawg Dreaming engraved key ring and Hot/Cold Coffee tumbler from you and your family and want you to know how great it looks and everyone it raving about how beautiful it is. The picture of The Old Dawg is really cute . I'm going to see if I can take a picture together with them and post a review on Google showing your handy work and end product. I'll get help and see if I can make that happen. Thanks for getting those out to me at this time of the year. B D is the 3rd of July and will start working to get to the 80th celebration in 2025. Stay safe and take care, tell the family Hi and Thanks so much. Fred.

Hey that's great to hear - so happy you liked it. Have a Happy Birthday Fred!

Leave it to me to be the cause of your first disappointment Gord! 😉🤣 Thanks for your efforts, my friend. Cheers. (Literally 🍻)

LOL! Hey not tat all . :)) A good exercise and learning. Talk to you soon Chris!

Would be interesting to see your settings with ceremark or whatever the spray is that’s used

Thanks. I will publish if I decide to give it a try. Cheers!

I've found that the thicker the glass, the worse it turns out. Try thinner glasses.

Well this is disappointing. Lol thanks for the hard truth! Time to go back to the drawing board. Because you’re right, if I was selling that to a customer I wouldn’t feel right knowing it’s probably not the outcome they were looking for.

A few folks had some ideas they put in the comments - film, etc, but not sure how much better it would produce. : )) And remember I am only 7 months in but pretty sure I can't get it better than this. Good luck and thanks!

Don't get down Gord - the CC glass, are you 100% sure it was an engrave by a Laser or done by shot beads? Anyway, thanks for memories of a few hangovers from CC and You and the Family have a Great Canada Day. Cheers

LOL! Not sure how it was done but glad it brought back a few good memories. Happy Canada Day to you all too!

Blazer Orange is what you need. It is designed to create that sandblasted look you seeking.

Question: I have a diode laser and my thinking is you must either mask or paint like tempo paint the area to get a good engraving. One other thing is what quality glass are you starting with. Just my thoughts on the quality work that’s being performed????

Hi Ronnie! Not sure of the quality of the glass and not sure how I would be able to tell. I thought about masking etc but saw several videos that tested them and they did not appear to make much difference but have you found that masking provided a better outcome than mine did, in this video? Thanks for your help!

@@LaserNUG try the tempo paint along with stuffing the glass with brown paper. I think you’ll get a better result!!!!!!

Most laser guys on youtube will say, " Buy the cheapest glas it engraves the best"

That is bullcrap, with a Co2 Laser, a quality co2 laser as you yourself have, find a crystal glas with not to much lead, that will help you not get cracked engraves as it what i belive makes the heat not getting to high, and it will be smooth as heck and be frosted look.

for my 60w epilog i use 100speed, 80 power, and Jarvis as diethering and 400dpi

@@patrikstoor Hey thanks very much Patrik! Greatly appreciated. :)

Where do you get your glasses?

@@trev0r15 Rastal