Це відео не доступне.

Перепрошуємо.

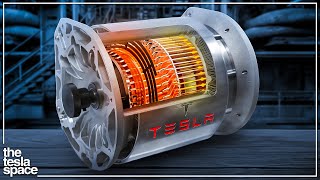

Tesla Motor the Secret of high Efficiency

Вставка

- Опубліковано 22 лют 2021

- In this video you will learn all about the types of electric motors that Tesla uses in their electric vehicles. So the advantages and disadvantages of the induction motor, but especially the advantages of the new synchronous motor with reluctance torque.

▬ More Videos ▬▬▬▬▬▬▬▬▬▬▬▬

Detailed video about induction motors

► • Induction Motor Types ...

▬ Website with Detail Information ▬▬▬▬▬▬▬▬

All Types of Electric Motors and Comparison

👉 oswos.com/elec...

▬ Social Media ▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Follow me on Twitter

► / markusscheven

#engineering #electricmotor #tesla

Great overview of Tesla's electric motors. Thanks for sharing.

Thank you very much, if you like you can share it.

First, thank you. The video is so helpfull.

Now, I have a question. Could you tell me why we divide the magnets? I need to more details.

As i understand, we divide to reduce losses in magnets,sheet and coil. But what are disadvantages?

How, do the segmented permanent magnets help reduce losses?

Thanks for your question. The segmentation reduces the eddy current losses. Normally, magnets are only segmented radially, but in very fast motors, they are also segmented axially.

@@Electric-Motor For this motor in video, the segmets are axially ?

Great video as usual.

What are the expected improvement using carbon-sleeved rotor in the plaid version of Tesla motor?

I read about advantages in motor speed, efficiency and power density but a lot more or just a bit?

Could the efficiency reach 97-98% in a greater range of loads?

Thank you very much for your question, it helps me a lot to achieve a better placement of the video.

Regarding your question... The carbon sleeve rotor will be used to increase the speed. As you have already written, this can increase the power density. This means that the motor can be made smaller and lighter. However, the losses in the sheet metal of the stator also increase rapidly. Have you already found a report on the new speed? I expect an improved battery that can maintain its nominal voltage over a longer period of time and thus slightly increase the efficiency of the electric motor.

Only aliens have figured out 100% unity

So if we want to improve the energy efficiency of an electric vehicle, the selection and modelling of AC motoros play a key role. What other things could we look at? I.e. higher battery density, what else?

For example, increase the copper fill factor or adjust the control to the electric motor.

Can you do a video about transverse-flux motors and circumferential-flux motors?

is transverse flux somehow using coils with different fluxes along the axle of the motor instead of around the axle? or do you mean axial flux motor?

Really grea videos, very informative and full of animations. Thanks for the videos...

Thank you very much for your positive feedback I'm happy that you like it, because every video takes a lot of time

Thanks for the great video, could you please explain how an additional current is needed to weaken the magnets in the PMSM, why would you need to weaken the magnets at the first place ? @ 1:28

With an IPMSM, you weaken the magnets to get more current into the motor at high speeds. This increases the power at high speeds. However, this does not mean that the efficiency also increases. You could of course use weaker magnets directly, but you would reduce the torque at low speeds. You always have to look very carefully at the operating points that are important for you when developing an electric motor. Hope the short answer helps you a bit?

Hi there. Do you know which motors are used in which teslas. Such as 3d1, 3d3, 3d5, 3d6, 3d7 etc. Which ones have how much kW of power? Some sites say the 3d6 has 220 kw, but some say the 3d6 has 239 kW of power. Which one is right. Also, which of the motors user hairpin winding? Is hairpin good or bad?

Thanks for your question and sorry for my late reply. Which models have which engines I can not tell you. In general, hairpin windings are very good for reducing ohmic DC losses. However, at the high speeds, the resistive AC losses are much more important. The winding head is also smaller with a hairpin winding, which is actually positive in terms of DC losses. However, the implementation of the hairpin winding is deficient with most manufacturers with regard to the cooling of the winding at the winding head. As you can see, Tesla currently has good reasons not to primarily use hairpin winding. Hope this infos helps and could answer your question?

@@Electric-Motor seems like the latest Model 3 are being shipped with new hairpin wound rear motors, any ideas on why? Is the manufacturing process easier / cheaper?

Good video..... kudos to the enginners..

Great Video, Just interested on where do you find that Tesla is cooling the PMs inside the rotor to weaken them? I thought, you weaken magnets by heating them.

Thanks for your question, I'm sorry but I think you misunderstood me.

Generally, you always try to protect magnets from overheating, so that if you weaken them with a magnetic field, they will not demagnetize.

Due to the design of Tesla's rotor ( embedded magnets in a V-shape), the electric motor has a lower back EMF and therefore needs to be weakened less.

The lower back EMF is compensated by a reluctance torque.

Therefore, the motor has fewer losses in the high speed range and a higher efficiency at both high and low speeds. Verstehst du jetzt besser was ich meine?

Do you understand now better what I mean?

@@Electric-Motor Thanks for the explanation!

Finaly Tesla joins PMSM. Toyota is using the PMSM motors since a more than a decade. My motor design is even more efficient than Tesla one, he he...

I took a look at your motor. It looks great. Does the motor have concentrated windings?

Tesla is claiming the motor torque is about 350-500NM depending on different models, so my question is the torque is after the gears or its just the torque of the motor?

Awesome Video! But can you make the sound volume louder for the videos? It's a bit hard to listen clearly even if I turn on max volume

Thanks for the hint, I will try to upload the videos in a higher volume in the future.

Hey ich wollte mal fragen wieso Tesla denn die Magnete überhaupt schwächen muss beim pmsm Motor

Das ist eine gute Frage, weil für das schwächen der Magnete benötigt man zusätzlichen Strom und verringert somit den Wirkungsgrad. Allerdings kann man durch das Schwächen der Magnete die Drehzahl des Motors erhöhen und somit seine Leistungsdichte steigern. Somit kann man den Motor kleiner, leichter und billiger bauen. Man könnte natürlich direkt einfach schwächere Magnete einbauen, allerdings würde dadurch das Drehmoment im unteren Drehzahlbereich sinken. Um das Drehmoment im unteren Drehzahlbereich wieder zu erhöhen müsste man den Phasenstrom im Motor erhöhen. Dafür braucht man aber einen stärkeren Inverter, der größer und teurer werden würde. Kurze Gegenfrage, wie hast Du es geschafft 121 Abonnenten zu haben ohne ein Video?

Are you speaking the language of the gods?

SO NICE EXPLINATIOINS THAKS A LOT

I thank you for your nice feedback

Great Video!

Thank you for your compliment

Also what is Air gap roll in electric motor performance?

This question is difficult to answer!

The smaller the air gap, the larger the back EMF.

However, this also reduces the maximum speed.

Because power consists of speed and torque, every motor has a certain air gap at which the highest power can be achieved.

If you are looking for a motor with a high power density, you should take a motor that has a high speed.

If you are looking for a motor with a high torque density, you should choose a motor with a small air gap.

As I said, not an easy question, but I hope the answer helps a little.

So if I add magnet to the shaft cages as see in the video I can get Better running time a cooling down

By using the magnets, the losses in the rotor are smaller and therefore you don't need a liquid cooled shaft. Hope this answers your question?

Sehr gute, informative und interessante Videos, gefällt mir sehr dass du so in die Tiefe gehst. Hoffe du bekommst bald mehr Aufmerksamkeit und Klicks. Was ist denn dein Hintergrund?

Vielen herzlichen Dank für deinen sehr netten Kommentar. Ich und mein sehr kleines Team optimieren elektrische Antriebe für die Automobilindustrie.

How many slots are present for winding also which gauge wire AWG number used in tesla model 3&s PMSM reluctance motor what is input voltage to motor how many number of poles??? can you Explain

Hello Thank you for your question. What do you need the information for or what do you have planned?

@@Electric-Motor in research of manufacturing EV Motors so can I get my answer? Also what is inverter used input voltage dc of inverter output voltage ac?

@@Rohit.G I am happy to help you with any questions, but I hope you understand that I am not authorized to share Tesla's design parameters. But it wouldn't help you because the control software has a significant influence on the performance of the motor. I am very sorry

How can reduce watt of bldc fan. If some have idea share

What matters most is a perfect match of propeller and motor. So that motor and propeller work at their best possible efficiency point. But that's hard if you don't have the efficiency maps of the motor.

very nice video

Thank you for your feedback, every comment helps :-)

Interesting details of the Tesla technology. Thank you.

Interestingly, the real technological advantage of Tesla is that you can no longer see it with the eye.

Nice description. I have some info that the efficiency of the tesla motor (IPM one) is something around 97%.

Thanks for your tip, is the 97% given at 20 degrees or 100 degrees motor temperature? It is very sad that the data of many of the manufacturers are never really comparable because the boundary conditions are usually not specified.

These videos help me a lot as I'm starting to learn about motors for work.

I'd like to learn more about how field weakening work for pmsm!

I'm glad to read that. Field weakening is actually a simple thing. But it is problematic that this term is also used for reluctance motors. But strictly speaking this is actually wrong

great work

Thank you very much, it's great when someone writes something nice in the comments.

How many poles can exist on 3 phases?

The number of poles of a motor is actually limited only by the number of stator teeth and the configuration of the windings. But please keep in mind that by increasing the number of poles you increase the torque, but you also decrease the maximum speed of the motor! And the losses in the sheet metal also increase with increasing number of poles.

great content but sound qualityreally needs improvements

thx for the feeback

No new videos? Can you make a video on how you can make your own motors at home? I would cnc and buy the magnets to make my own at home.

Hello you're absolutely right, I have to make a video again. However, it gets me down when I work 2-3 weeks on a video and only get a few hundred likes for it. While a cat or dog video gets more than 1Mio. views and you do not have to invest time for it. But I already have 3 new videos prepared, which I only have to record. But you gave me a good idea how I can help that everybody can build his own motor without doing complex calculations. I do not have a solution yet but will think about it. Thanks for your comment, it helps me to go on

@@Electric-Motor Hope you go over which software we can use to simulate magnetic design for hub motors.

@@Electric-Motor If you want easy content, you can make DIY motors and show everything you did. and use those motors for small fun projects. You will get attention once you get something cool looking on your thumbnail. Ill be sure to share you around the EV community.

Very nice overview, thanks for sharing this video

My pleasure!

"Second home of Tesla"!? Tesla first opened their HQ in Palo Alto, CA, US. Then a factory in Fremont, CA, US, then a factory in Reno, NV, US, (possibly count the Tesla Solar factory in Buffalo, NY, US too), then an electric machine development office outside Athens, Greece, then a factory outside Shanghai, then one outside Berlin and then a factory in Texas, and a new HQ in Austin, Texas...

Tesla was looking for a lot of employees and because we are also located in Berlin I supported them a little bit. So that people become aware of the location. My goal is always to help people, it's my thing and I enjoy it. Nevertheless, thanks again for the other information, many have certainly not known so.

can you please tell me how to select magnet type, decide V angle of the magnets., length, width, thickness and position of he magnets in the rotor?

and shape of the magnet? Please help me to find answers of above question.

The best angle and magnet length and thickness depends on how much reluctance torque you want your motor to have. Maximizing the reluctance torque has not only advantages but also disadvantages. Normally you need a special software to design the electric motor. Such a software then needs hundreds of parameters to make a calculation. To make it faster you need optimization algorithms to serve the calculation software. My tip would be to start with a block design without V-segments. This way you can test the influence of more and less magnetic material. If you really want to start with V-segments, the design of Tesla is a good starting point. With magnets of different strengths you can then try out how you get closer to your goal. May I ask what you want to build?

@@Electric-Motor thank you very much for your response.want to develop 4.5kW rated power, 20Nm rated torque, 60Nm pk torque IPMSM motor for Electric Two wheeler application.

@@AkashDeepSingh-dq2ty Sounds like a great project. Then I would suggest to buy a motor and vary the strength of the magnets. The second step would be to make your own design for only the rotor. Are you doing this for a company or just as a hobby?

@@Electric-Motor Can you please share your email-id. I can share you the detail there. Thanks

Low sound. Amazing video

Thank you very much for your compliment. I apologize for the poor sound quality, I'll try to do better with the next video.

fix your audio and you will rock more!

thx for the feeback

What is the size, cost, life, speed, and torque of the PMASynRM

Thank you for your question. I'm sorry but it would be unfair to Tesla to share the exact details of the electric motor. I hope you are not angry with me for that.

So what is the difference between ipmsm motor in prius and ipm-synrm motor in tesla?

Hello, The operating principle used is actually the same. The Prius motor is much shorter and has 8 poles in the rotor instead of 6 like the tesla motor, if I remember correctly. Accordingly, the configuration of the stator is also different.

@@Electric-Motor I just wonder why Tesla motor is called ipmsynrm when its just regular ipmsm. What is synrm in this motor?

@@mantis23101988 You are absolutely right, unfortunately the internet is 90% crap, the informations are mostly not really wrong but nonsensical. The Tesla motor would also work without magnets, which would then be a poor synchronous reluctance motor (SynRM) that would of course have much less torque. Important SynRM is not equal to SRM. SRM stands for Switched Reluctance Motor and is also shortened to SR Motor. Hope this has helped you a little bit?

@@Electric-Motor yes, a little bit. Thank you.

Great video sir.

Sir, may you provide some guidance on design of PMSM, I am working on this..🙏

Hello, I'm happy to help you! I don't know of any PDF or book that describes the design of a PMSM well. Most books mainly describe the theory. What software do you use for the design?

Sir I am working on ANSYS Maxwell software

Sir @oswos my first doubt is regarding sizing ... How did we get to know about what size (means dia of stator, rotor...) is to be kept..!

I have specifications of motor

Ansys Maxwell is very good but already the third step! You have to use an analytical tool first to get a feeling which parameter has influence on the torque and the speed. You can use Rmxprt for example. This is not the best tool but it is also from Ansys. If you work at the university then it is easier to get licenses. The second step is the thermal design of the motor, so design the of the cooling. Have a great day

Great, very interesting.

Thanks 👍

Thank you very much, may I ask what you think I should improve about my videos in general?

@@Electric-Motor At the moment I think your videos are ok.

It would be interesting next videos about drivers (inveter), such as the principle of operation, characteristics in general and of power electronics and so on.

Thanks!

Thanks for your feedback, I would also find it great to make videos about control and inverters. However, I do not have the time and therefore I try to focus only on electric motors.

@@Electric-Motor it's ok anyway.

I will be waiting for your next interesting videos about electric motors.

Thank you!

Whent for a Raptor

Diy please

I am still thinking about exactly what application to make a DIY video for. What do you think is a good motor application?

Do you need extra money for videos, you can start a patreon and sale a class how you can make, design, and cost effective way to make a high quality motor.

Thanks for the tip and all your comments, that helped me a lot to get more views. Please let me know if I can help you somewhere.

your audio volum level is too low !

Thank you for the hint. Do you mean the language or everything?

@@Electric-Motor all ! I mean your media system volum level is too low compar to other channel .

@@chakramaharjan8462 Thanks again for your hint! I'll try to pay more attention next time! I worked all night to finish the video today. It's really easy to make little mistakes when you don't get enough sleep. I hope you liked it anyway?

@ 2:17 he made a custom hub motor for this fully custom made e scooter

ua-cam.com/video/7K5IV8N2QbA/v-deo.html

this is not the Tesla principle, this is Mask, not even Bedini !

What do you mean by that?

@@Electric-Motor Ceea ce a gândit Nikola Tesla in anul 1890 nu seamănă cu ce prezentați Sau ați preluat numai numele . Pentru dumneavoastră este corect ceea ce prezentați .

Exista un muzeu Tesla ln Belgrad pe care îl recomand să-l vizitați !

Sorry with the name most people think of the cars these days. But I also have great respect for Nikola Tesla and his inventions.

Grüße

But isn't the switched reluctance motor even better? And fantastically simple to manufacture.

And in the synchronous reluctance motor, the low reluctance iron pathways for the flux look as if they may be structurally weak, to me.

As for the neodymium magnets, China's monopoly on these rare earths is not a natural monopoly, but one which the Chinese themselves brought about by price manipulation. I would call that an "act of war". Rare earths are not rare at all. They could (and should) be mined elsewhere.

It gives me great joy to read comments like yours, because you are absolutely right about many things!

Yes, the structure of the synchronous reluctance motor is mechanically poor and unsuitable for high speeds.

And yes, rare earths are not really rare on Earth and most states have simply underestimated their importance.

And yes, there is actually no electric motor easier to manufacture than the SR motor.

But, the efficiency of a SR motor is worse than a motor with permanent magnets, especially in the lower speed range.

It is not easy to explain but try to compare a SR motor with three phases with a permanent magnet motor.

In a SR motor with three phases, only one phase is active at a time, while in a motor with permanent magnets, two phases generate torque simultaneously.

This means that the power or the current to generate the torque is distributed over two phases.

Can you give me a short feedback if you have understood the example so or maybe you have another opinion about it?

@@Electric-Motor

I am always pleased to be the bringer of some sort of joy.

But I am not an expert in electric motors. I am a casual observer.

I have noticed that the Swiss manufacturer: ABB has introduced a new range of synchronous reluctance motors. And the American company: Turntide has a range of switched reluctance motors. Neither company concedes that the other design is better! But both make claims when compared to the ubiquitous AC induction motor.

I cannot claim to follow your explanation of why the permanent magnet motor is superior [meaning it is more “efficient” or provides greater torque, etc].

The way ALL electric motors work is that the magnetic forces pull or push the rotor from the existing position to a new position. Normally this new position would be more magnetically “comfortable” for the motor. But just as it arrives in this position, the electrical current through the coils gets switched to make a new magnetic configuration, and the rotor must move on again. In the early days, the switching was achieved by commutator rings.

In modern AC motors the switching mechanism is more sophisticated. But the idea is still the same: let the magnetic forces pull or push the rotor to a new position. And then at some optimum moment, rearrange the magnetic forces in order to promote further rotation.

Using power electronics - like thyristors (which is a relatively recent development), the ability to direct the magnetizing currents to different coils at will, under intelligent software control opens up new possibilities. And if you want to activate two coils at the same time, this can be done.

Constraints might arise because of switching speeds, and the “dragging” effect of any hysteresis which might pe present. I don’t know any of this for sure. I am guessing. But I will look out for any published test results.

I notice “Turntide” says it uses no sensors inside the switched reluctance motor, which I also find intriguing.

It seems that you are very involved with electric motors.

May I ask why you are so intensively involved with electric motors?

Small hint... You can operate almost every electric motor sensorless! The question is if that makes sense and if you want to accept the limitations.

@@Electric-Motor

I am not involved with electric motors in any way.

But about two years ago, I developed a casual interest in electric vehicles - especially Tesla. The development of battery technology is the really distinguishing feature of electric vehicles. But I also wondered how Tesla could power an AC induction motor from what is necessarily a DC source - the battery. Thus I was introduced to the pleasures of "pulse width modulation".

By the time I had digested the workings of Tesla's AC induction motor (used in the model "S"), Tesla had moved on to "reluctance motors" (for the model "3"). So I learned about "synchronous induction" motors, and (just to be safe) about "switched reluctance" types, too.

There is a lot of information available about Tesla's technology. There is almost a spin-off industry created by following Tesla developments.This is very like IBM in the 1980s. It is far more difficult to discover information about Tesla's rivals. So I tend to follow only whatever Elon Musk decrees for his Tesla.

But, diverting as looking at electric motors might be, the critical technology in electric vehicles remains the battery.

As for sensors in motors, I would not exclude them as a matter of principle. And I imagine the very least your motor controller needs to know is:

. 1) What is the orientation of your rotor?

. 2) How fast is it spinning?

If these are not questions which need answers, then I obviously have more to learn.

That is correct the motor controller needs the position, speed and phase current.

Position and speed can be calculated by an observer. The observer contains a model of the electric motor from which it can estimate the position and speed.

However, the method is not 100% accurate and also takes time until enough measurements are taken and the correct position is determined.

For pumps and fans this is a common method, but not for traction drives and actuators!

Have a nice weekend

electric Vehicles need electric motors which are brushless carbon brushes always tend to wear out very quickly

Electric motors normally are highly efficient

Wish you a happy new year. You have a really nice picture as icon. Honestly, most electric motors are highly efficient only in a very small range, for electric vehicles this is usually not enough, so you have to reach into bag of tricks like Tesla.

cant understand ! rubbish audio.

Do you think the volume is too low? Or something else? Thanks for your feedback