Broaching on Your Haas Mill! We Have the Tools & the Templates - Haas Automation, Inc.

Вставка

- Опубліковано 8 чер 2024

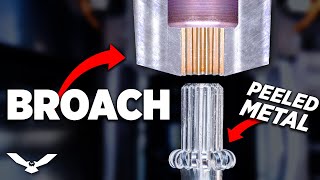

- A couple years ago Haas introduced broaching capability on our lathes. Well, now Bhop Singh is back to show us how to do broaching on a Haas Mill. We've added new broaching templates for the mill control and we have a wide selection of broaching tool holders and inserts available on HaasTooling.com. Also be sure to check out the Mill Broach Tool Alignment video linked below.

IMPORTANT CAUTION: As of 1.18.23 the Mill Broaching Template is in beta test. So please verify the path of the generated program in graphics and also run the broaching cut without a part loaded (air cuts) before commencing with actual machining.

Mill Broach Tool Alignment video:

• Aligning a Broaching T...

Here are links to the Broaching pages on Haascnc.com where you can find the tools, inserts, and the download links for the VPS template files.

www.haascnc.com/haas-tooling/...

www.haascnc.com/haas-tooling/...

www.haascnc.com/haas-tooling/...

Feature Try-out (Answer Man) video link:

• Try out a Haas option ...

Broaching on a Lathe video link:

• Broaching on a Haas La...

Don’t miss any Haas videos. Click here: www.haascnc.com/about/Newlett...

Need more reasons why you should consider a Haas? Check this out: www.haascnc.com/whyhaas.html

If you enjoyed this video, please hit the like button and share it with a friend who’ll find it helpful . . . and thanks!

Follow Haas: Facebook - / haasautomationinc

Instagram - / haas_automation

Twitter - / haas_automation

LinkedIn - / haas-automation

Code: YI6FJ37TSI39J5YO

Code: ORBYOQWTWPCHFGVD - Наука та технологія

Haas has turned out to be a company that has done more for the American Machinist than any other... the Toutube videos no small part of that feat... You have made a fan of me... thank you Haas.

"we have hammered these mills mercilessly" ....good to see I'm no the only one that works a Haas like a sock puppet..lol

😎😎👍👍…. I’ve never regretted buying my Garage machine from you folks, stuff like this makes it even more valuable. ⭐️⭐️⭐️⭐️⭐️ to HAAS and the folks working there that make building a profitable Side Hustle very possible.

We've been broaching with our old Haas 50-taper mill for years. Producing internal splines every day. Most important is to have probes on the machine, then all extras are working that is needed - M19, G68 and so on. It's not that difficult to write a single spline subprogram using G91 for stepover and then later G68 rotation for next spline and repeat. But very good video Haas, thanks!

I knew you could do broaching on the Haas by making your own custom macro, I never knew it was a canned cycle already. let alone Haas having broaching tools. CNC broaching tools seem to be so uncommon, it's good to know Haas carries them.

Been broaching like this in a Haas machine for a long time. You can also achieve a program like this with macros, which keeps the program nice and small.

Thru coolant broaches give about 20 time tool life in our experience. We were broaching ratchets by moving the broach off centre line. 45 teeth with 6 passes on each in en8. Ran thousands of those a week

Great guide video. Always informative!

lovely, would love to see spline broaches for involute 45 degree fine toyota splines.

hope ya make a spline video when they are available been looking for broaching toolholders

I would recommend Haas to re-write the cycle on the retract of the tool, go out of the material when you retract for a better wear on the insert.

When you have to do lots of these operations it's way better for tool-live. 🤔😉

Good info, thank you 👍

It would be nice to add in a widening option to be able to cut slightly wider keyways.

Please add external Broaching to the mill template! I was excited to see broaching added to VPS until I realized it was internal only.

thank you

👏👏👏👏

If memory serves correctly, broaching a 20 mm keyway is about equivalent in forces to drilling a 14 mm hole. Good indication that this is not harming the machine in any way compared to 'normal' use.

Forces spread across 360 degrees of bearing rotation in the drilling cycle. Full load on 1 degree in the broaching.

@@John-ik2eg So all 5 axis trunions are just falling apart from working at 0° degrees? Bearings can take huge loads even statically before taking any permanent deformation. If the load was enough to brinnel a ring statically it would instantly wear a groove on the rings of thr bearings as soon as the load was applied when spinning, and drill thrust for example is seriously underestimated

@@Sketch1994 *Interesting*

The difference it when drilling the spindle is turning and not stationary. I wiped out my spindle bearings doing this

Please make video on knurling

Can the ISO-20 taper CM-1 do broaching in aluminum, with small stepovers?

could you add two features to one being the ability to shift the key to the side to allow larger keys to be made for example 3/8 broach taking 2 passes side by side = 3/4 with our building to much pressure.

Another is could you please order the shanks in inch as well as metric. Like for 1inch& 1.5inch holders

Can it make tapered keyways too (or would I need to tilt the part)?

I use our software at work for this, but I add a G187 P1 E.05 line. Takes off up to 30% of the cycle time. Does the vps incorporate something like this?

Are the vps templates already installed in the machine? If so, where do you find them? If not, how does one obtain them?

Is the broaching template for the lathes a free upgrade or does it cost money?

CaptainKlutch, Both the lathe and mill broaching templates are free upgrades. Just go to the download links on the Broaching page linked here www.haascnc.com/haas-tooling/broaching.html . . . there is also a link to instructions on the same page for installing the templates on your control.

I have a Haas VF 2 SS EU 2018 ,

is this a Option for this machine ?

Late 2019 dm-2 with vps, macro, spindle orientation. What do I need to do to add this cycle?

Bill Knighton, The VPS Broach Template files for both Mills and Lathes are on this page (also linked in the description). There are also instructions for installing the template files on your control. www.haascnc.com/haas-tooling/broaching/broaching_toolholder.html

can you use a g156 cycle on a super mini mill?

Isn’t it risky putting a load on the spindle bearing when they aren’t turning. I tried this and it wiped out my spindle bearings

Hanzhen harmonic drive gear , strain wave gear reducer, robot joint , over 30 years experience

I see an awful lot of cycles on this guy's VPS that is not on mine....anyway to update the control/download those newer VPS cycles?

csprinkler, If you go to this "Broaching" page (www.haascnc.com/haas-tooling/broaching/broaching_toolholder.html?op=/haas-tooling.html&oh=broaching) and click on the Haas Broaching Line dropdown menu you will find links to the various broaching templates and installation instructions. Here is the link to the installation instructions. www.haascnc.com/reference-container/haas-tooling-references/vps-template-installation.html

@@haasautomation Super, thanks! I'll give that a try.

Hello, Its possible for an VF2 YT EU ? i Dont have the VPS choice for broaching ! Thank You from France !!!

Hello GTH Transmission, The VPS Broach Template files for both Mills and Lathes are on this page (also linked in the description). There are also instructions for installing the template files on your control. www.haascnc.com/haas-tooling/broaching.html. These templates are available on both the EU and US version websites. Thanks.

@@haasautomation All is perfekt Thank You

Isn't that how you put flat spots on bearings?

k, listen to what Bhop has to say at this point in the video about our experience using this type of broaching on our own machines here at the factory. ua-cam.com/video/js3Jx3FgBwU/v-deo.html

no big deal I been broaching all 4 square corners in wave guides on my cnc's for years.

Technically, this is SHAPING, not BROACHING! A shaper has a single cutting tooth. A broach has multiple cutting teeth.

Only thing I disagree with,

You shouldn’t have to pay for add ons, it should come with every canned cycle and g code, it’s bull sht

I agree other brands all have this built in

Haas machines are cheap, kind of accurate, work horses. I'm not saying Haas makes a bad product. I do have to agree with you in this instance. There is absolutely no reason to need the rotational offsets feature when you can just as easily change spindle orientation instead.

The way the macro is written requires increment in x, just easier to rotate by g68 especially when doing wide keys requiring a y offset, just gets messy in code otherwise.

You could go buy an okuma or mazak or fanuc instead, and still have to pay their prices for the options, many of which are a hangover from the patents and copyright that GE put on these functions from the 60- 80s.

@@halomaster985 eh, relatively cheap not super cheap, they are mid to low tier on rigidity and accuracy. My base model eco turn 450 dmg mori will repeat size and location less than 2 micron, yet the comparable haas lathe will vary about .0015 per part sometimes😂 it’s sad. The only thing absolutely amazing about haas is the user friendly controller with all the extra features, and the tech support is top of the line

@@adammiller4879 Tech support has been pretty lackluster in my experience. Repairs are a complete joke, but that's more due to Sellway having a monopoly on Haas service.