Top Features to Look for in a Full Automatic Slider Type Winding Machine

Вставка

- Опубліковано 10 жов 2024

- GW-7005

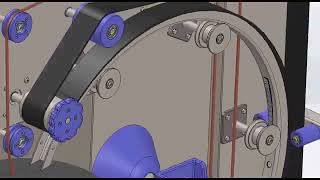

Top Features to Look for in a Full Automatic Slider Type Winding Machine

As manufacturing processes evolve, the need for precision and efficiency has never been greater, especially in industries that rely on high-quality coil winding. Full Automatic Slider Type Winding Machines have become the go-to solution for businesses that prioritize accuracy, speed, and productivity. But with many options on the market, what exactly should you look for when choosing the right machine for your needs? Below, we explore the top features that make these machines indispensable for modern manufacturing.

1. High Precision Winding

One of the most important aspects of any winding machine is its ability to wind coils with consistent accuracy. Full Automatic Slider Type Winding Machines excel at delivering high-precision results, ensuring that each coil is produced within tight tolerances. Look for machines with programmable settings that allow for adjustments in winding tension, speed, and coil layering for maximum control and accuracy.

2. Automatic Wire Tension Control

Inconsistent wire tension can lead to defects in the coil, affecting its overall performance. An advanced Full Automatic Slider Type Winding Machine should feature automatic wire tension control systems. This function maintains consistent tension throughout the winding process, reducing errors and the risk of wire breakage, and ensuring uniformity across all coils.

3. User-Friendly Interface

A Full Automatic Slider Type Winding Machine should have an intuitive, easy-to-use interface that allows operators to set parameters quickly and efficiently. Machines with touch-screen controls and advanced programmable logic controllers (PLCs) enable quick adjustments and real-time monitoring, making it easier for operators to manage complex winding tasks.

4. Flexible Configuration Options

Flexibility is key in today’s diverse manufacturing environments. The best Full Automatic Slider Type Winding Machines offer multiple configuration options, allowing them to handle various wire types, sizes, and winding patterns. This versatility means the machine can be adapted for use in different applications, whether for transformers, motors, or other specialized components.

5. High-Speed Operation

Time is money, especially in high-demand production environments. Full Automatic Slider Type Winding Machines are known for their high-speed capabilities, which can significantly boost production efficiency. Look for models that offer rapid winding speeds without sacrificing accuracy, ensuring you meet your production targets while maintaining quality standards.

6. Durable Build and Low Maintenance

A reliable winding machine should be built to withstand the rigors of constant use. Machines with robust construction, including high-quality steel frames and components, reduce downtime and maintenance costs. Opt for a Full Automatic Slider Type Winding Machine with a proven track record of durability, backed by comprehensive warranties and strong after-sales support.

7. Real-Time Monitoring and Diagnostics

Modern Full Automatic Slider Type Winding Machines often come equipped with real-time monitoring and diagnostic features. These systems allow operators to track the performance of the machine, monitor production in real-time, and detect any issues early. This leads to fewer production interruptions and increases overall efficiency.

8. Safety Features

Safety should never be overlooked in industrial equipment. Choose a Full Automatic Slider Type Winding Machine with built-in safety mechanisms, such as emergency stop functions, overload protection, and guarding to prevent operator injuries. Machines that comply with international safety standards give peace of mind and reduce the risk of workplace accidents.

9. Energy Efficiency

In today’s environmentally conscious world, energy efficiency is an essential consideration. Some Full Automatic Slider Type Winding Machines are designed to minimize power consumption while maximizing output. Energy-efficient machines not only reduce operational costs but also align with sustainability goals.

10. Customizable Winding Programs

Advanced winding projects often require specific winding patterns or custom parameters. Look for a machine that offers customizable winding programs, allowing you to pre-set your desired specifications for different coil types. This feature enhances versatility, reduces setup time, and ensures that each product meets your exact needs.

www.coilwindin...

Linkedin:reurl.cc/xL3lo1

UA-cam:reurl.cc/xL3l8Z