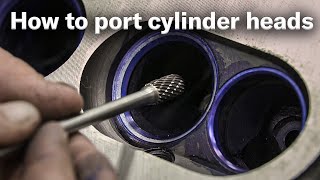

Cummins 5.9 Fire Ring Machining and Head Porting By Bias Boring the Valve Ports Unusual Mill Setups

Вставка

- Опубліковано 6 жов 2024

- In this video I have to take a bunch off the deck of A Cummins 5.9L Cylinder Head in order to convert it from C-rings to fire rings. I also do some updated head porting by boring the bowls of the ports to get the exhaust and intake heading in the right directions. This is a delicate process that requires careful attention since this is still a wet head and taking a bunch of material out of it is a risk to go thru into the coolant jacket. Hopefullly it is gains and not Junk I wind up with! Stunt milling at its finest I hope you enjoy!

Things are getting SERIOUS! I can't wait for next years VE Dyno Day. Brian is gonna bring the FIRE!! Beautiful work as usual!!!

Got to do all I can since I am going to be under cubed and undervalved compared to the competition 😎

Sounds like my old puller, modified MH44 with a single 427 pulling against allisons and multi engine machines! At least it was cheaper when I broke!

Nice work Brian

Always like seeing the HBM Machining.

Have a great day.

Just goes to show that with a creative mind set you don't always need to have the fancy toys to get the job done. Nice work!

Another fine looking job. Thanks for sharing...

And thanks to these I run these fire rings in my Subaru sti and the radius cut grooves with the fire ring pretty much did the trick. It’s a high hp build with head studs and now my Cummins is getting them, center finder and a milling machine

👍👍👍 thanks for bringing us along feller..have a good day 👊

If only we could fast forward like that on the horizontal mill that would be nice. This is when normally a journey man or master machinist or myself will have the auto stop set and go get another machine started and keep an eye on both of them while cleaning the shop up.

I’m always looking forward to a new video from Brian and he has done another excellent job with this one. Thank you.

Another great job. Thanks for sharing. Can't wait to see the power numbers.

That avatar is great!

going to be sweet to see old yellow on the road again

Cheers Brian

Put a scrap head up there and take .036" off in the first pass... for all us UA-cam viewers, you owe us !

Good engine. I’ve got one in my 1640 combine. 3000 hrs and still seems good!! Looking for a exhaust elbow off the turbo. No luck from used parts guys, new is NLA.

Cool setup!

Nice job Brian! Hope the guy you doing it for knows what he has in knowing you. The head should work great!

good video brian

So the rumor of you having the intake shelf cut off and then welded back on for porting was true :)

How do you think I got good welding cast iron? 🙂

Sweet! Blessings

Happy Sunday Brian!🛠🗜⚙️

Cool

You're a Titan of Non-CNC 😂

Nice!

I would think the HBM has more than enough power to drive a BIG shell mill.

Is there a reason you fly cut all these heads and blocks?

The shell mills don't leave as good a finish and even my 12" face mill won't cover the full face of most of these heads and taking more than one pass leaves a transition it might only be a couple of tenths but it always will. When you are trying to seal cylinder pressures that can spike over 20000psi even the little variances matter.

@@bcbloc02 I guess I'm a little surprised that a face mill has poor surface finish, or that it would matter as much with fire rings as shown here.

But I certainly understand what you're saying about not being able to cover in one pass.

Thanks for the interesting video and your reply! 👍

Big shell mill also has alot more tool pressure, so prone to chatter especially with the severe interruptions, and since you want to clamp delicately on a part like thos so you can cut it in a free state this could give you a bad time.

Big face mills are for Big parts, where theres enough meat to dampen vibration and so you can clamp it tight tight.

What kind of flow numbers are we talking about? Apparently It's not aligned with the valve guide angle?

I didn't have this head on a flow bench so I can't say other than it dropped the boost by 10 psi and raised the drive about the same so I know it is flowing a lot more. Well if you go by the boost pressure being linear it would have been about a 25% gain in flow.

I gotta ask... What kind of cutter are you using to cut the ports?

It’s a twin blade adjustable boring bar.

What do you get on working over a head? Fire ring and porting

Depends on how extensive the job is and what level of performance the customer is after. Typically $1500-$2500 for the machine work and porting if you get into upgrading valve train components you can spend a lot more depending on how exotic you get.

@@bcbloc02 do you have a way I can contact you or a business page of any kind

My contact email is listed under the about section on my channel. Also it is simply my channel name at yahoo dot com.

What are you going to do in order to keep the compression in a "reasonable" range? Turn down the piston crown? Marlon

Head is flat won’t change compression much

The 5.9 is a flat head. You can get a number of “fat” gaskets if you need to. Of more significance is maintaining your valve recession. It took me almost two days on an old Bridgeport round ram to deal with the guides. I bored them out to about 1/2 inch. Don’t remember exact number. Machined 24 mag bronze guides and drove them in. Counter bored valve spring seats. The only issue I had was #6 where O didn’t have complete guide coverage on one exhaust guide due to exhaust plenum design.

But the engine worked great. The 5.9 Cummins is one of the best engines ever made. Crude, reliable, long lasting and pretty good on fuel.

Someone once told me not to fire ring a street truck. Do you agree with that? Did you just set angle that you went in at by feel, or is there a degree angle that someone has come up with?

On a street truck that is up to you and how you use it. Fire ring is much more effective esp. at higher temps and compression pressures. But it costs a lot to have it done. As I do all my own work, I just go ahead and fire ring the beast. My 5.9s are for my day to day driver and my back up shop generator. I don’t race.

You should post some videos of your machine work. I would love to learn some methods that I can use on my Bridgeport: )

@@dm-zx7xb I have been in a three year legal fight over my old home. I am now having to move. Just finished moving 150,000 pounds of assorted machine tools. My channel went dormant as a result. But as I move forward, there will be a channel documentation of the new shop and home. Massive amounts of timber framing, machine tool moving and set up, etc. several machines will finally be restored to better than new. Lots of engine work. Steam engines, gas engines and diesels. Complex milling work on Bridgeport’s and other machines. Tool and die work for the shop. Wadkin machines from England and US machines. Scraping work including autocollimation of ways. In short, major! I have found some of the video of my work on the first 5.9 Cummins engine. Not the most professional video but many of us have had to learn the tricks of Hollywood to keep UA-cam happy. Best thing to do is subscribe to Devmeister Super Precision and hit the bell icon to get updates as they begin to flow.

Too much time with the tool spinning. (with nothing else happening) Ron W4BIN