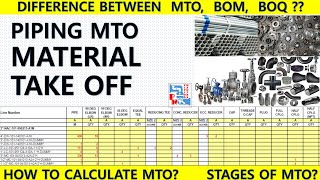

PIPING BILL MATERIAL OF ISOMETRIC DRAWING/ SHOP MATERIAL DESCRIPTION

Вставка

- Опубліковано 14 вер 2020

- Bill of Materials (BOM)

Key Learning Points

Identify what is a Bill of Materials

Identify the purpose of a Bill of Materials

Identify the personnel involved in compiling a Bill of Materials and using a bill of materials.

1.1 Bill of Materials

A Bill of Materials (BOM) sometimes referred to as the Material Take Off (MTO) lists all the items that go into a finished project or subassembly of that project. The Bill of Materials can be structured in levels indicating all the steps to final completion. This can let the bill of materials look like a tree with the finished good or subassembly as root.

1.2 Purpose of the Bill of Materials

A bill of Materials has different functions depending on which level of the BOM you have and job description you are carrying out.

For example in pipe fitting you could have the following layers:

BOM for each individual piping isometric

BOM totals for all the piping isometrics for the clean steam system

BOM totals for all clean systems that use high purity piping

Customer name

Project description

Company Job Number

Person who prepared the BOM

Drawing number

Revision number and date

Component description

Component

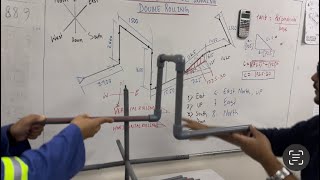

Tell about fit up and complete detail of 45 degree offset

This channel tell about

Structure diagram

Isometric diagram

P& I'd information

Lay out of plan diagram

Pipe fittings

Material code of SS and CS and alloy and other material

Find out travels and degree in structure

Dummy support

How made elbow

Fabrication formula's

Piping best formula

Structure formula's

Degree cuts

Difference between tube and pipe

Measurement tape

Type of fitting

Rigging

Folding

Type of exchanger

Vessels

Project of oil and gas

Isometric diagram

American standard fitting of pipe

British standard of pipe and structure

Fertilizer projects

Hydro testing of pipe lines and exchangers

Maintenance of exchangers and column

Interview question and answer of piping and structure

Fabricator

Fitter

Supervisor

Pipe type

Exchanger type

Fabrication world

We provide all type of knowledge and practically experience with you for your batter feature and build up you for your family because mechanical field wants theory and practical experience

Work with safety CALCULATING OFFSET FOR 45 DEGREE ELBOW

TAKE OFF 45 DEGREE ELBOW

CALCULATE TRAVEL

CALCULATE RUN

CALCULATE OFFSET

What is a pipe offset? What is a rolling offset?

In doing some pipe works, we sometimes encounter situations wherein we have to connect two lines of pipes that are not quite aligned with each other. These two pipelines could be offset horizontally or vertically. When we see a combination of both horizontal and vertical offset, or in other perspectives, a combination of offsets in two different directions, we call it a pipe rolling offset.

To deal with pipe offsets, we can use a bent pipe fitting to change the direction of the pipeline and another bent fitting to return to the final direction of the pipeline. In this calculator, we tackle how to find the travel length, which is the length of the diagonal that connects the two points at which the pipeline changes directions

subscribe now this channel

Material Size

Material Quantity

An example of a typical bill of materials is given on the next page.

2.2 Purpose of the Elements

The information recorded on a Bill of Materials is used to provide traceability and accountability for companies:

Customer Name: Often used as the first method of dividing and filing information.

Project description: Is used to sub-divide and file individual projects for one specific client.

Company Job Number: This is used to track cost elements in a project and is assigned to materials and labour so the all costs can be tracked.

Prepared by: This identifies who prepared the bill of materials and ensures accountability for it’s accuracy. In large organizations it also allows for someone to query information given in the BOM after it has been issued to site.

Key Learning Points

Identify the key elements of information for a Bill of Materials

Identify why this information is critical

Describe automated systems for generating bills of materials.

Pipefitting Drawing number, revision and date: This ensures traceability and is used to ensure that the most up to date information is being used.

Component description: Basic description of the component required, e.g. Pipe, elbow, flange etc..

Component specification: This gives detailed information on the material to be used. This information is used by the draughtsman to complete the drawing, the purchasing personnel to order the material and the pipe fitter to verify that he/she has received the correct material. This reference will call up a piping specification which will give detailed information on how the pipe line should be installed, supported, inspected, tested and much more.

Material Size: Indicates the size of the components required.

Material Quantity: Indicated the quantity of the components required.

![[English] Piping Material Codes & Specification](http://i.ytimg.com/vi/1YQ9dpa6_lw/mqdefault.jpg)

Mzher

This is such a helpful video. Please keep sharing, it is much appreciated, thank you Sir.

👍👍

Indeed it is good lesson

thank you sir. very good information

Thanks for your valuable comment

Very good explanation.

Very informative video .Looking Forward to More videos sir . Kindly Upload more videos

Behad umda jaankari diya aapne. Thanks 👍

thanku from bd🇧🇩

I am understand bill material Thank you👍

You are very welcome

Thanks vai

Very nice explained.. Thank you.

Dapat may pilipino din na ganto na nagtuturo

❤❤ you are very skilled trainer

Excellent class

Sir please teach us rolling drowning

Thank for this video sir

Easly understand any direction in drawing

Thank you sir ...great site knowledge

Thanks for presenting 🎉🎉❤

Good clear you the Best

Very useful full video sir thank you

Love u sir so much.. Today first time i watched ur video.. Hats off to u.. your way of teaching n making understanding is so incredible.. I appreciates ur hard works n my blessings 👼🙏❤ for u dear respactable sir... Today u helped me a lot.. I am a fresher in Piping but I will remain continue with ur videos.. Wow.. Thanking u a lot..

ua-cam.com/video/Ye-bJgcJIjo/v-deo.html

I like it you are video bro and thank you so much bro more give it video

Thanks and sure

Good information. Future please make some practice explanation with piping components. However yours all' post are amazing. Thanks please make more videos about piping

Thank you

Thanks sir 🙏

it's indeed a good lesson for me, nice one.

Explained very easy way

Very underrated video

thank you, sir

Its Is Very video, I Understand how Read Isomatric Drawing

Great channel very helpful 👍🙏

very Good Explain

Very very useful video

Thankyou sir

I m really happy sir

Veery good 👍 sweet sir......

Thank you well explained

Make more videos on the topic

thanks very super

Thank you for brief explanation

Tamjham teacher

Good video

Very help full sir your vedio

Good I understand

I love the way you teach and explain it, you are the best sir.

ua-cam.com/video/Ye-bJgcJIjo/v-deo.html

Have a look

Very helpful video sir.

Thank you. Sir👍

Спасибо большое

Very helpful video pipe fitter

Super sir you are explain good

Very helpful videos sir

Very good👍👍👍👍👍

Very helpful sir

Thank you sir ❤️❤️

You are welcome

very good thinks

Welcome

i read someday isomatric piping drawing on youtube.but i can't understand but i watched your video about isomatric drawing i compeletly understand easly thanku. nd i requst you make a video P&id drawing explain.

U r welcome dear

Thanks for your valuable comment

Good speech sir thank you🙏

Good

Thanks

Top

Thnk you sir. Too many basic are clear.

Good sar good sar aage template

Thank you Sir.

Very Good video

This is very helpful video

Thanks

Thank you sir, keep it up

Po

Very good

Dear viewers kindly make correction weld number 01 is FW

Ok

OK...

good

Valve direction is important to point out. Nice video though.

Thanks. Very useful

Thanks buddy.

Tank you for is morooco

Nice sir

Excellent explained

Very clear. I want specific training online.

Glad to hear that

Today I subscribed your channel. It's Informative and helpfull during this new normal situation.

Kindly share about Piping supervisor duties?

what are the essential knowledges required to a piping proffessional?

how can we successfully crack any piping interviews?

Thnk u sir... Usefull

Thank sir

Mahdi Saleh Al-Mashhad

Thank you very much sir

Very helpful video sir how to marking of pipe double rooling

Ahmad jameel Al Ali

كثر منها 🫶🏻🫶🏻

Yes ! wonderful video extremely comprehensive ! I am new in this field but i found a missing information about item no 12

there is no given position to this item so i believe there is no possible way to put it on my free will ??? so if you are so kind to

explain this to me . thank you very much !!

please create a video on Billing and measurements sheet

Türk dilində variantı olsa çox yaxşı olardi , bizdə yaxşı başa düşərdik

🫶🏻🫶🏻 كثر منها

Easily I understand sir

How do you find heat #. sometimes finding the heat number can be a little tricky on pipe fittings

Mujtaba Ahmed

Hi..very interesting so how will I know what material it is by just looking at the drawing?

Do make video on... How to find out elbow center of 30,45 and 90 degree physically by using measuring inch tape

Tafazul Adil dear I will try to make videos on this topic.

@@pipingtechnicaltrainer3522 thanks sir g in advance...

@@pipingtechnicaltrainer3522 are u providing technical Certification Course?

Tafazul Adil yes dear

@@pipingtechnicaltrainer3522 so can I have the course list that u r offering

Up load RA bill video of an project in any CGD

Which metal use for this pipe line

clearly samajh hua or video lekar aao sir aur drawing ke bad kuchh bhi hai Na sab kuchh batana sir

can you pls explain how to calculate cut pipe length?

pls explain more about cut pipe length

ziyad adnan Al Khudair

Sir i have a question what is the length from sf to threaded olet? Can you explaine the standards of bill of materials?

Good explaned. I want You to teach me online and I pay you

Sir,the , what means the sectional part in the drawing,.

Isometric drawing me kaise dekhte hai ki material kaun sa hai

Good Sir...But Hindi me rahta to aur achha hota.