Cylinder Head Porting with Cylinder Head Flow Test

Вставка

- Опубліковано 20 бер 2009

- Cylinder head porting for off-road and racing engines.

Cylinder head flow test on a Flow Performance electronic flow bench.

Cylinder head porting theory:

The air/fuel mixture is introduced into the combustion chamber through the intake port and valve, and expelled from the combustion chamber through the exhaust port and valve. It is this system of ports and valves that give the impression that the internal combustion engine is just a big air pump. In a way, it is. The point is, the more air the engine can pump, the more power it can produce. That is the theory.

Cylinder head porting explained:

If you can think of the internal combustion engine as being a big air pump, then by increasing the volume of air through the engine, power should increase. One way of increasing air flow volume is by a method called “porting”. Porting is a method of improving the aerodynamic properties of the intake and exhaust ports and their valves

Because of casting and machining limitations, ports often have sharp edges, casting flash, intrusions and narrow areas that create friction, restrictions and turbulence in the flow of gasses. Most cylinder head porting is done by grinding away sharp edges and casting marks, and enlarging areas of restriction or intrusions occur allowing the free flow of gasses through the port, thus allowing more air volume to flow through the engine to produce more power.

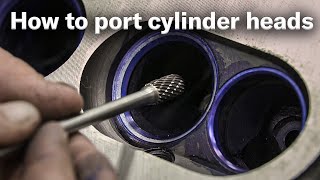

Cylinder head porting tools:

Electric or air powered grinders equipped with long shank carbide cutters are the tool of choice for removing material, blending sharp edgesA shank of 4 to 6 inches will usually handle most cylinder head ports. After the carbide cutters are used to shape the port, the port walls are smoothed with stones or sand paper rolls.

The grinder used in the video is from Harbor Freight. Having the ability to adjust the speed is a big help. The grinder in the video does not have a speed control, but a good quality router speed controller may help.

Most air grinders offer speed control, at least by adjusting your compressor pressure.

The 6” carbide cutter in the video is from Summit Racing.

Gloves, goggles and ear protection is highly recommended.

A small LED light on the end of a flexible shaft will help illuminate the port for good vision.

For the more professional porter or someone interested in the best performance possible, a flow bench and velocity probe enable the most efficient port shapes.

Cylinder head porting CNC:

Porting cylinder heads by CNC, or Computer Numeric Control, is becoming more popular as CNC machines become more available and lower in price. One big advantage of CNC porting is consistency from port to port.

Cylinder head porting DIY:

Do It Yourself porting is a popular way to make more power from your off-road or racing engine. It is considered “free horse power” by many. But it is easy to ruin a cylinder head by grinding into a water passage or other cavity within the cylinder head. The DIY porter should stay conservative in their porting efforts to avoid such a catastrophe.

Cylinder head flow bench:

A flow bench is a tool that can measure the volumetric flow of a cylinder head, as well as intake manifolds, carburetors, exhaust manifolds, air filter just to name a few. By checking your work as you perform your porting, you can see where you are making gains and where you are wasting your time. The flow bench in this video was built using the Flow Performance FP2.0BS flow bench kit.

Cylinder head port velocity:

The velocity within a cylinder head port is important depending on the application of the engine. Ports that have small cross section areas offer high velocities and tend to yield higher levels of torque, especially at lower RPMs. Ports that have large cross sectional areas will have lower velocities than a smaller cross sectional area port, but tend to produce more horse power at higher RPMs.

Cylinder head velocity probe:

A velocity probe is a tool that measures local velocities within the port. The air speed, or velocity, is not constant in all areas of a cylinder head port, especially at low valve lifts. By probing a port with a velocity probe while the cylinder head is on a flow bench, areas where air is traveling faster than other areas are generally considered a good place to try to make improvements.

Cylinder head gasket matching:

Gasket matching is where the material of a manifold or cylinder head port are opened up to match the opening of the gasket that will be used on the manifold or port. The objective is to make the transition from manifold to port as smooth as possible.

Links of further interest:

Flow Performance flow bench kit FP2.0BS…

www.flowperform...

Flow Performance flow bench kit FP2.5BS…

flowperformance...

Flow Performance flow bench build….

• DIY Flow Bench Build f...

Flow Performance velocity probe demonstration…

• Velocity Probe in Cyli... - Авто та транспорт