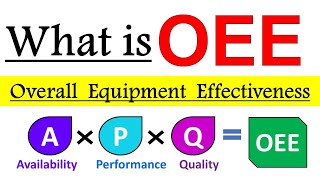

OEE - Overall Equipment Effectiveness TPM 2nd Pillar - Kobetsu Kaizen Focused Improvement Pillar

Вставка

- Опубліковано 7 вер 2024

- OEE - Overall Equipment Effectiveness, TPM 2nd Pillar - Kobetsu Kaizen or Focused Improvement Pillar, and TEEP - Total Effective Equipment Performance, are all explained. OEE is used in LEAN Operations too. It is an excellent metric for equipment utilization or machine utilization. The concept of HIDDEN FACTORY is brought out and the need to look at OEE before making investment in more equipment is shown up.

Rashmi Kamkar, Khushboo Sharma, Amrsha Srivastava, Shubhangi Srivastava, Shraddha Nemane, with Dr G (Dr Shrinivas Gondhalekar) created this beautiful, pleasant, colour coded video to explain OEE, the Six Big Losses, TEEP, Hidden Factory, and the relevance to financial management. We have also attempted to demonstrate that learning can be a fun filled process.

How to eliminate the losses would be covered in another video on Kaizen.

This video honours the ladies starring in this video, who mastered OEE and applied it in industrial situations, helping eliminate some of the big losses.

ITC Babes

Very informative video

Very good explanation

Thank you for a very nicely and well-made video. To the point, yet in-depth information.

Thank you team, for such wonderful explanation of overall equipment effectiveness

Thank you, Pratik. So nice of you.

One of the best videos from your team, explaining the complex topic of OEE. Keep up the good work ! Looking forward to next video.

Many many thanks Satish. We always value your opinion.

Satish Pendharkar Hello Sir, Thank you for your kind words. We are delighted to hear your appreciation and are now more motivated to keep making videos. Thank you so much sir.

Thank you so much sir, your appreciation makes us strive harder everytime.

Another video which was not only fun to shoot but also was a great learning!

Shoutout to Dr.G and the team for always teaching important concepts with such ease and fun!

Yes. Please let me know. Thanks to my entire team.

Very Simple yet effective demonstration of OEE.

And Thank You Sir for making the concept of TEEP this easier and meaningful.

Thank You Dr G and team.

Thanks Kushal. Yes TEEP is fairly ignored by industry. TEEP is brilliant because no one can manipulate the Calendar time of 525,600 min per year (non leap year). The denominator gets fixed.

Watching this video after revising the first pillar of TPM, extremely simple to understand. Thank you, Dr G and team!

Soumya Naik, MnE

Thank you Soumya.

This video ensures OLE.. overall learning effectiveness!!. Thank you Dr. G and team for this great video.

A person who knows something very well can never complicate it! Dr G, absolutely love your videos. I keep watching them at intermittent intervals to revise my concepts!

Thank you Shivani.

Well explained sir 👏

Thank you

Awesome sir

Keep going

Good team work

Thank you very much.

OEE calculates the Equipment losses, TEEP calculates both Equipment and Scheduled losses and Kobetsu Kaizen aims at individual and continuous improvement for attaining Zero losses. Thanks Dr. G and team :) Looking forward to learn Kobetsu Kaizen Chart preparation !

Important concept, well explained in simple language and visual demonstration for better understanding. It's worth watching :) Thank you for bringing this to us.

Welcome, Alisha. You are taking lot of interest in these subjects. Much appreciated. Anything else I can do for you - please let me know. Dr G

Very nicely explained Sir . Hats off to you and your team for making complex subjects easily understandable through examples one can correlate 👍

Happy faces with prettier explanations... Thank u😊

Welcome. You may like many more videos on this channel. Our effort is to bring some profound knowledge, which is very important but not readily available. There is one on Kaizen: ua-cam.com/video/VwtbXnzEWtA/v-deo.html

Snippets from Japan: ua-cam.com/video/YAkSJzy2jok/v-deo.html

@@DrG720214 sure, thank you, i will definitely watch them all😊

great video.thanks

The video gives an idea of all the 6 losses that affect the efficiency of the equipment. Nicely demonstrated with colourful charts. Waiting for the next video!

Creative way of explaining a difficult concept, the charts for demonstration are like serving as photographic memory of the core concept.

Thank you sir and team for coming up with new ideas and sharing useful concepts.

It's explained slowly so getting easily cleared and fitted in mind.....very enthusiastic leader....

Useful feedback. Thank you.

Eagerly awaiting your next video on how to avoid such loses.

TEEP measures OEE against the Calendar time.

Thankyou Dr. G and team for such colorful presentation and detailed explanation.

Very effective video, waiting for the next video on the third step of Tpm

Thank you Dwiti. Coming up by early November 2019 at the latest

Thank you sir. That is great

Voila! Yet another informative video by Dr G and Team ,loads of good wishes to them for keeping us updated on more such theories and very relevant information!525600 Mins is a good time to improve on the current situation!

Thank you Arushi. Looking forward to more information-packed, fun-filled videos.

Its amazing to see you sir and your team explaining such complex topics with simple approach and tools. Must say you have just not raised but have altogether changed standards for others in the field 😊.

Thank you Harshal.

Thank you Dr G and Team for another great video. The hardwork behind scripts, shooting and making the concept easier is really appreciated. 🙏😊

Thank you Snehil. You too had put in all that hard work behind the videis.

Another great video. Loved the colours... learning can be fun! 😄

Heyyyy jolly new topic and my expected one... thank you so much guys...

Great video sir! I remember you telling us about how important OEE is and this is a very simple explanation. Thank you sir. Eagerly waiting for your next video on kaizen!

OEE explained in a very lucid manner Sir.👍

Thank you Subodh.

nice editing and presentation....

Thank You

Excellent & great

Thank you for your appreciative comment.

Got an idea about the 6 different losses which affects the efficiency of the work. Waiting eagerly to learn how to eliminate these losses. The splits in the total planned time is a new learning for me. The importance of having high value for quality time , which enhance s the OEE was clearly presented in the video. Great efforts by the team in explaining these new concepts. Thank you sir!

Yes. Thank you.

Very informative

Great. Appreciated Anmol.

very nicely explained the what are the various losses which are happening in a plant

and also how can we calculate Overall Equipment Effectiveness

thank you for this video

waiting for the next one

Thank you Nitin. Glad you looked this up.

Eagerly waiting for the next part 😊

Thank you.

Thanks Dr G and team for the video. If possible, pls upgrade the video taking technique and the sound recording quality 😀 .. u guys are great 👍

Thank you for your appreciation. We work with simple tools. However we will certainly look at upgradation. Thank you again.

Learned all the 6 looses which depends on availability and quality. Waiting for kaizen video.

Thanks Nancy. Kaizen video should be up shortly.

I was waiting for the video ever since Sir mentioned the term OEE,also talking about the next topic "Kaizen",the improvement in visual representation using color coded charts is appreciated.Can you please consider making a video on PERT & Critical path ?

Yes will look at PERT CPM. Good suggestion.

Such a helpful video😊. Does the planned time involve replacing the bad quality product as well?

Planned time is the time you want the machine to run perfectly making good quality.

So the answer to your question is NO.

@@DrG720214 thank you sir.

Sir I have one question. In my industry There was an machine A, machine B and machine C. Consider machine A as an bottleneck it's cycle time is 100 and my Machine B cycle time is 60. Suppose if my machine B gets breakdown for last 30minutes of the working hour,My machine A running with full efficiency during the full working time. There was an inventory made for Machine B for the next day. Then iam getting loss for the first day due to breakdown and my second day I was achieving 100% OLE and also through the entire month by making the inventory for machine B . Is this possible or not?

It is possible in the example you gave. However, this is the old way of thinking. The new way is to create zero defect, zero breakdown situation. TPM is very useful for that. THe new way questions fundamentals and corrects things at the root, rather than make adjustments. The difference is one of designing the system for failure or designing for success. Zero breakdowns are very much possible.

Sir , performance can vary operator to operator... Depending on his or her speed to operate....Means equipment effectiveness changes with person...Is this statement correct??????

Not correct. The standard time is set based on the machine capability, and product; not on the operator.

To the point, yet in-depth information. Thankyou sir!

(pgdm-BD)

Thank you Aryan.