DIY Lego Blocks - Do They Fit?

Вставка

- Опубліковано 7 кві 2022

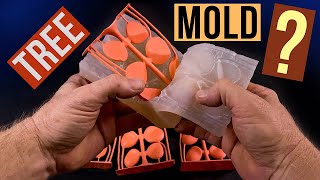

- A big problem with resin casting is that cast objects are a little bit smaller than the original part. So cast parts might not fit with other parts in your project. The question I answer in this video is :

Will resin cast Legos fit together will genuine Legos?

This is important if you want to make custom pieces to go with your Lego constructions.

Thanks to the following companies for supplying the materials used in this video:

Econosil-25 Silicone Rubber

SilCast 2 Urethane Resin

UD Dyes

I buy my casting supplies at www.silpak.com

Here is a list of suppliers for many of the materials I use in my videos:

www.dropbox.com/s/kz6mhmf7v5v...

Do you have a project to suggest for the channel?

Here’s a .pdf with everything you need to know:

www.dropbox.com/s/pjb0l6fr7zj...

This was really useful to see not just for Legos, but for seeing how tight tolerances in general translate to resin! Just the result I was hoping for since I'm going to cast screw threads.

I saw several people use a Lego plate as the bottom of their mold. Those became the registration marks for the second half of the mold, and you don't need to worry about tape or glue holding onto the silicon too tightly.

To the last bit of "sculpting lego compatible parts": Now that is where the shrinkage WILL seriously come into play. The bigger the piece, the worse shrinkage gets, proportionally.

It is probably economically infeasible to cast your own Lego pieces. A genuine basic 2x4 Lego piece just a few cents each. The material of self casted piece alone costs more than a few cents. It is a fun exercise thro. A testimony of economy of scale.

Lego company is incredibly litigious it seems. There was a site once that had 3D printable Legos, it got taken down.

It might be fun to create Lego macros: use Lego to build a component of a larger model and then capture that in a mold with all the exposed connection surfaces preserved. Then that component could be cast in resin over and over again. Now you could build your Lego model with a combination of these macro modules and regular pieces. Imagine a castle with a lot of symmetry and repeated structure: build each chunk once and amplify through casting, then assemble.

I use those Scotch mounting pads all the time. I’ve found a mist of ease release on the adhesive solves any bonding issues, and the thing is so sticky it’ll still grab your model and create a nice seal.

This is gonna be a huge hand in making colors of parts that don’t exist

Missed opportunity of not building the mold box out of Legos.

Ok. I have to say it. I have seen a lot of people make a mold case out of Legos, but this is the first time I have seen anyone make a mold case for their Legos. 😆

I’ve seen people use Lego to build the casting box.

This is encouraging. Along with your Crafsman collaboration, I was thinking about revisiting a project I shelved. I pulled out some old K'Nex figures (made of nice pieces with ball-socket joints and a ton of articulation) and was going to make a 2-part clay-up mold with them but never got around to actually pouring any resin. A squish mold looks like the better option. Good to know that the tolerances on rubber/resin, while not quite up to Lego's exacting standards, would probably be perfectly fine for the K'Nex parts.

We see the difference between silicone mold pouring and injection molding into metal. :-) Love your videos!

I've been planning a mould with that hinge set up so I'm glad to see it works.

Really entertaining and informative, Robert. The de-mold on this one was truly edge-of-your-seat stuff!

That was an amazing casting! All those tiny little crevices and not a single bubble in the silicone or the resin! Very impressive! I’ve been hoping you’d do a Lego casting, those little things are just ingenious.

I never thought about casting and I will probably never do it BUT your videos are super interesting and entertaining. I already watched a bunch today and enjoyed it. Thanks :)

I was really excited to see a new pouring technique. The explanation about scaling down the pour seems so simple and obvious, but I can't imagine coming up with it myself. It reminds me how much value there is in learning directly from a professional, no matter the craft. Thank you for sharing your expertise!

This was a really fun video, I like how you manage to come up with an interesting subject each time. Always look forward to them

i've always wondered this myself, thanks for the video!