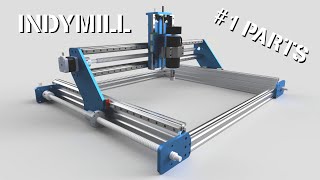

IndyMill - DIY CNC Machine #2 Assembly

Вставка

- Опубліковано 3 жов 2024

- Assembling the IndyMill - DIY Open Source CNC machine made out of 8mm steel plates, aluminum profiles, linear rails, ball screws and Nema23 steppers.

More info: indystry.cc/in...

Buy parts for IndyMill: indystry.cc/st...

Support my projects on Patreon → / nikodembartnik

You can also support me via PayPal: www.paypal.me/...

Ball Screw 650mm: bit.ly/2vYFJVq

Linear Rail 600mm: bit.ly/3c1IFAO

Profile 2080: bit.ly/37TCdsl

Profile 2040: bit.ly/3bUZ6zb

Stepper Motors: bit.ly/32i70xT

Stepper Drivers: bit.ly/2Pehg5d

Ballscrew tool: www.thingivers...

Ball screws, linear rails, NEMA23 steppers, big stepper drivers, steel parts, custom controller and big spindle (I want to upgrade 500W spindle to 1.5kW spindle later). This will be a serious DIY CNC machine! But still, the main focus is to make it easy and inexpensive for others to replicate :) Any ideas, questions leave them in the comments!

Instagram: nikodembartnik

#indymill #cnc #diy

i am building my own cnc with completely different design , however i always come to watch this video for brain storming inspiration, your build is so simple yet extremely effective

Nikodem... I am so in love with your project, and impressed with what you have achieved, that I do not want to make any negative comment... BUT I feel I must; a number of other comments refer to the lack of anything to handle linear thrust in the ballscrews. They are intended to be used the other way around; the end without the thread fits into the flexible coupler, while the threaded end is where a thrust bearing and various collars and spacers are fitted to the transfer the lineal thrust to the frame. At present, this thrust load is being taken by the bearing at one end; this would be OK as long as the bearing is one designed for this function. The other end however is using the flexible coupler, and the stepper motor to handle thrust loads... this may work OK for a time, but it is likely to be less effective, and will accelerate wear on those components. Better fixed now at little cost, than later when you have to replace expensive parts.

When I see one of your videos in my notifications, I drop everything to check it out! They never disappoint me. :o)

Hi, I am currently designing something similar but having 2 parallel ball screws for each axis, with a single motor for each connecting by a closed loop timing belt. I am wondering why the "standard" configuration for a ballscrew is one fixed bearing at the motor end, and one free bearing at the other. Could I just use a fixed bearing at both ends? Would that provide better rigidity?

Thanks

How do o opinyon

Ftyf fotncnc

@@____5837 do you found answear? I wonder this samw

@@hinduspl you only need a fixed bearing at one end, and the standard machining only allows for a fixed bearing to be screwed on at one end. While you can also use a fixed bearing at the other end, it will just act as an expensive floating bearing, with no benefit. If you were to custom machine a ballscrew to accept fixed bearings at both ends then your could get some benefit in spreading the force out, however you would need very tight tolerances to have it work correctly, and might have issues with differential size changes with temperatute

@@____5837 so the fixed bearing is holding ball screw at the end, and the other end of this ball screw is attached directly to the stepper motor and then motor is holded to base? So there's no bearing support on the end with motor?

Looks great! 2 things i have to mention. First dont use 3d printed parts for the ball screw nuts because all the cutting force goes in it (you can buy premade really cheap). Second use some proper ballscrew supports like BK BF blocks at both ends this 3d printed part with a ball bearing in it cant withstand the force and will give you backlash play. Dont wanna sound neardy but i allready build 3 mills myself and learned a lot from it! If you need help with parts i can help you. Keep on your great work allways fun to watch!!!

This. Your printed bearing holder will not withstand the forces and the bearings of the motor are also not made for those loades. The nut holders are way to weak and i would go with a proper (smaller spindel for z. But a really great project and I'm looking forward to the next parts

👏👏👏👏👏

Absolutely agree!

@Manuel, I've just started looking into a diy cnc... are linear guides such as the ones Niko has used here worth it over using wheels on v-slot?

pj hi. If you want stability in your machine i recommend using linear rails. The best ones to use are hgr15 or even better hgr20. With rolls you will get to much vibration in it. for 3d printer it ok because there is no cutting force!

I am enjoying this build. Many people will give you their opinions on what they think you should do differently but the fun of doing these projects is to find out for yourself what does or doesn’t work and modify your design as you see fit. Your assembly looks great so far. I’m looking forward to the next part of the build.

What you are saying is he should reinvent the wheel. He should be learning from others experience instead of making those same mistakes again. This is how technology progesses when people build upon others work and improve it.

powiem szczerze , to jest jedna z najlepszych cnc domowych frezarek!!!

As a Maker myself I am impressed with the simplistic design of your Indymill but have a few reservations that have been mentioned by others in regards to the ball screw brackets, direct drive from the stepper motor etc.

One thing puzzled me, you had dual linear rails on the X and Z axises but not on the Y where there would be flexibility present on the single linear guide, this really needs to be a dual track and will make rigidity much better.

A niggle of mine is people using fastenings without washers between the head of the fastening and the surface of the part. This helps spread the locking load and also minimises damage to the part surface. Threadlock is another definite requirement.

I am not being negative on your achievement as this has to be one of the best self builds I have seen for a long time and it has all of the core requirements to be a great starter machine for anyone interested in entering the CNC world.

Well done on a great project!

I was checking every day for the sequel of your first video. You should have seen my smile when all of the sudden, IT WAS THERE! :)) Thanks! I'm planning to build according to your build assembly to add the machine to my business. So many new things you can create if you have access to a CNC.

This is a great video series! I am on summer break from school and had no plans to build one of these until I started watching these videos starting with the Dremel CNC. I wanted something with a work area of at least 24" x 24" so I knew I would have to do some modification. I started by simply recreating everything in solidworks exactly as he provides it by converting or redrawing all of the laser cut and 3D printed parts. The website has links to everything he uses so with some work, it is possible to find dimensions for purchased parts. In many cases it is even possible to find parts already made on Grabcad like linear rails and blocks, ball screws and bearings, etc... Once it was put together the way he has it, the first thing I did not like was the way the ball screw was mounted and supported. I couldn't figure out for the longest time why he did not use the fixed and floating bearing supports that came with the screw. I finally realized that the screw he links to does not come with those components. So I re-designed around those. I think his thrust bearings are probably okay but the way the screw bearing mounted to the x and y axis just looked super weak. It did not take too much to modify those to fit.

Once I had that done, I re-configured the Z axis. I don't know why he mounted it the way he did and used a belt drive with a lead screw instead of a ball screw. Not that the decisions are wrong, I just figured why not stick with a ball screw and direct drive it? I also wanted to make the final tool interchangeable. I specifically wanted to be able to add a diode laser and possibly an enamel injection setup(don't even know where to start with this) I also found that the Makita RT0701C router is actually cheaper than the 500W spindle and provides a lot more power so I had to design around that.

Once I had everything in place, I could figure out exactly how much I was going to need to extend the x and y axis in order to accommodate my 24" x 24" cutting area. I ended up using 800mm ball screws for both the x and y. Currently the design is set up for a 200mm z axis ball screw but I am not yet certain that is where I will end up. Ball screws are dimensioned based on the total length, not just the screw length. So that 200mm screw once you add the bearing, does not provide 200mm of travel. I also had to add spacers to the x axis motor mount in order to maximize the available cut area without going up to the next size screw. This gained me about 24mm.

My plan is to 3D print all of the flat panel components to start. Once I am up and running, my plan is to re-cut those parts from aluminum. I am starting with NEMA 17's hoping that they are enough but understanding that I might have to upgrade. They are cheap and I can always find something else to use them for. After all of the redesign, I think the only other 3D printed part is the mount for the router. I will probably dumb that down and CNC it as well. For now I am using something I found on thingiverse that looks robust enough to start with.

I just started printing the parts tonight. I have 2 Dremel 3D45 printers plus access to another one plus 3 Dremel 3D40's if I get anxious about the timing. 24 hours of total print time on 2 printers just for the y axis plates. That's two prints at 12 hours each....

I want to stress that I am in no way bashing what has been done here. I would not be motivated without everything he has provided and the videos he has produced. Without his starting point, it would have taken me much longer than the 4 days it took me to get where I am. Probably long enough that I would have given up.

I’ve spent a lot of time looking for a affordable cnc to mill small accurate parts from soft metal and all are much more expensive and not even as good in most cases

Keep up the good work ur brilliant dude👌👍

Thanks for the manual. Very instructive. I start sourcing the parts.

Nikodem - you do a great job presenting your builds. I'm gathering parts to build your designs.....Thank you!

Thank you!

How do people give this a thumbs down for this awesome content?

Try turning a centering tool (45° chamfer) for your drill press and start the tap with it. You need to keep the tap *absolutely* center and straight. The little dimple in the top of the tap is for just that purpose. Slightly chamfering a drilled hole before tapping helps a lot too.

You need a fixed bearing block for the ball screws , by not using the bearing blocks the cutting loads will damage the stepper motor bearings. And the 3d printed part the connects the ball nut to the steel plate is tiny it will flex and it will cause shatter, you need to beef it up by alot. The name of the game in CNC "the bigger, the heavier ,the stiffer" the better.

Important point there. His solution will also introduce some play which makes the use of "playless" ball screws useless in comparison to normal lead screws.

Also it might be good to tear town and clean the cheap MGN rails and blocks. I found quite some metal chips inside of mine when I cleaned them before use.

Third point is the squareness of the whole construction isn't checked at any point. You should not trust in the squareness of the cuts of aluminium extrusions.

These things show there is a big difference between industrial design and DIY/maker design - no offence I enjoy your project's.

It will take sooo long to destroy the stepper motors that way that most likely it's not gonna happen, maybe after using it all day long for few months. When it coms to 3D printed parts, I know that it's not a good solution, I want to later upgrade that with something milled out of aluminium or maybe bended steel. We could go on like this forever and make a $100k machine from this project, but that's not the point

@@nikodembartnik I understand your point, but if you are going to follow this path of "stepper holding all thrust loads" you will inevitably have to switch the couplings and/or re-design the 3d printed bearing holders. These spider couplings are not made to transfer axial loads and have no defined axial positioning (only made for torsion loads, rotation), so if you apply compression/tension loads (cutting forces) they will move and create backlash. Loads pushing the ball screw away from the stepper will have to be carried out by the bearing which is not axially located on the 3d printed part (given enough repetitive force the bearing will move in the 3d printed part), and loads pushing the ball screw to the stepper will compress the coupling until it bottoms out, and then they are not actually helping with misalignment anymore. I suggest that you use a simple rigid coupling (even 3d printed) instead of a flexible one, if this topology of the design is to be kept.

Keep up with the good work, though!

Thanks for your tips, now I see what you mean and yes indeed that may be the problem because those couplers don't hold together very well. How about a 3D printed "case" for the coupler that will keep it in place and at the same time let it still be a coupler? Maybe eventually I will replace those coupler we will see. That's why I don't want to share any design files yet, a lot may change :)

First off. Love your work I have a scaled up 540x500 dremel cnc.

I work with large cnc's everyday (makino, mazak, mori seiko etc). As all others have stated you need the proper end bearing blocks with thrust bearing and lock collar to set the stretch of the ball screw. The ballnut also needs a proper metal housing to transfer the torque to the gantry plates.

Another thing I've seen with rails that small is that they can deflect, especially since you have not used all the holes in them to secure them to the frame. It will add a Ton of rigidity. I've been able to push rails of that size over 1/2" when 3 or 4 bolts have snapped off and that was a servo door!

If you do the upgrades and slap a 2.2kW spindle on there. It will probably cut aluminum quite well. Keep up the good work.

Dang, this looks well thought out and designed. Also looks like you are saving money in the right places(exept maybe the bearings for the ballscrews). I might built one of these. Exited to see the next episode!

Thanks a lot :)

Excellent project 👍

It looks great and really heavy! Perfect for a good CNC! Excited about the finished machine 👌🏻

Looking forward for 3rd part . Take care in these time

Very elegantly engineered!

Love this project, thinking of following your steps and make one my self

Just do it!

Those 3D printed adapters between the frame and ball screw heads are going to introduce a lot of play in the movement. Swop them out for something metal asap!

Use a tapping block to hand tap. you will break fewer taps. block with close fitting holes for tap to fit in while tapping. They are cheap. When milling plastics, use a squirt bottle as a mister to keep the plastic cool.

I m in love with your CNC design..

Great stuff 👍 can't wait to see it running.

beautiful..just add some more.the nema 23 you can bolt it from the back.so just thread the hole there and no need bolt and nut anymore.

Good spot bro

Nice job Nikodem!

This is so great (yet again) cannot wait until you're done and I can buy/build one myself!

Even now it looks amazing. Great idea and good job making it free :)

Fantastic! I love your projects. Only an advice, I know that is not the final assembly but I would actually suggest if the ball screws are long enough to extend the motor mount and place another ball bearing on the other side as well otherwise it will be prone to vibration close to the NEMA with only the not rigid couplers. The best would be to print naother ball bearing sopport and mount the motor just outside with spacers. Pplus you gain some X, Y travel.

The 3d printed coupler between the ballsecrew and the portal will screw (sic!) your accuracy. I highly suggest to make a metal version.

Very nice project man & clever design

Thanks!

Another awesome video - thanks for posting!

You´re already a great engineer. Congrats!

That CNC machine looks great!

Really like this project, good job!

I do hope to see this project go above and beyond, but you will need to take a lot of the constructive criticism provided by some of your more experienced viewers. Lots of potential here, all the best!

i like that design very much. i think im going to adapt it a little to my own application.

Nice work on the new CNC! Also your videos are definitely more professional now then your videos back in 2018 and 2019, you have indeed improved the filming and editing skill. Subscribed.

Very well designed. Congratulations!

Excellent project, thank you for providing a parts list!

Nice Job Nikodem! Good luck with all your projects.

Fantastic! Looks good and strong 💪🏻 I can't wait to see it in action 👌👍🏼

Well done Nikodem keep designing ,another nice video:)

Looks like you forgot the ball screw mounting adapters (BK12 or BF12), you shouldn't just attach it to the stepper motor.

Better use FK10 and FF10 bearings, could be easily integrated into the smaller plates

a.aliexpress.com/_d8grQcx

Also should there be a plate behind the two rails forming the portal to stiffen it up for torsional forces and forces in z direction for example when drilling straight down.

+1.... I was dying inside when seeing it. Nice looking machine and all but using a ballscrew without proper end bearings is a waste of time and money.

As has been stated, the bearings in the stepper motors is not adequate. They are not designed for axial loads. This will likely be one of the first problems you will need to address after you get it all working.

EXACTLY

Looking really great, Nikodem!

I'd love to see what you can design when you build a hypercube coreXY 3d printer

You use super strong and rigid parts for everything (steel plates, linear rails) but you use a tiny 3D printed part to connect the steel plate and the ball screws

I am afraid it will flex or might even break

I will update that later with something milled out of aluminium or bended steel

@@nikodembartnik Good reply. It doesn't need to be perfect straight away. Nice project Niko! Don't let the comments get to you. You're videos are improving too! Dan.

At the 8:53 min of video you have self locking nuts but the bolts are too short. I recommendet you to replase the bolts with some longer because you dont reach the teflon part of nut whitch it lock the bolts. It is CNC machine and there are many vibrations and not locked bolt can cause a various problems not only with accuracy. BTW nice video and good job!!

Love the way you printed those bearings! I’ve been looking for an end block support for my 1000mm ball screw, nice to see I can press a bearing in a printed holder!

This is a great project and channel, really looking forward to #3. My grandparents on my father's side came from Iwonicz in the early 1900's.

Awesome project, looks very neat!

I see you still have not addressed the thrust forces on coupler. There should be some kind of collar or fixable thrust bearing on the machine side of lead screw (vs the motor side). You have ball screws to minimize backlash but all a waste if the coupler can flex?

Ogladam Twoje CNC filmiki i widac ile radochy Ci to przynosi. Zastanawiam sie czy nie wybrac CNC jako mojej pracy dyplomowej z inzynierii ;)

Great work Niko, some beginners mistakes but in my opinion I rather like to say enjoy the next steps ;)

a decent drill press would be a good investment o 3o; it helps a lot for tapping, or just drilling holes. But you did it just fine

Just bought one few days ago :)

Why use ballscrews and not proper bearings like angle contact bearings?

Might as well save the money and use leadscrews.

Balmscrew are the state of the art more expensive but very reliable and precise. In your version as Nema17 motors are upgradable to nema23 you can buy cheaper one then if not enough satisfied upgrade to this version. Hi

Cool work Cool work space

Please add descriptions about the parts and tools you used

great tool!!!

Hej Nikodem . Zaczyna zacnie to wyglądać 👍👌. Pozdrawiam

Wonderful @ sincere effort . Nice work 😀👌

Hello, what type profiles You use? V-slot? or T-slot? Regards.

It is possible to attach a plasma cutter to this machine and with it make the blue metal parts for replicating your awesome project. Keep going

Very nice touch to use. Tweezers to place the t-nuts😏

To make that look good on camera, you have to do stuff like this, otherwise I would cover whole scene with my hand :)

You're awesome, keep up all the great work!!

You should use your dremel-cnc to machine aluminium-parts (instead of steel) for the indymill and use the 1st indymill to machine the aluminium parts for selling ;-) ... and then a black hole appears :-)

Hello. I wait your project ! You are good man

First off, awesome job so far. It looks very promising. Next, I was just wondering if you have any information you could share on the steel parts used in this build such as the cad designs maybe and who you went with to get them cut. Any help would be greatly appreciated! Keep up the good work. Thanks!

This is really cool, but would be great if you sold kits with everything ready to make this. Of course with a premium for the extra work. Would be a good way to make money even. Some people (like me) have more than enough money and don't mind if it takes time because you are a startup company, but I still want this machine in a simple package with less hassle. Similar to how Prusa has done for 3d printers. They still make the plans open-source, but they also sell a massive amount of kits with instructions like a 3d printer from IKEA. Would be convenient if you also got something like that. I got your newsletter anyway.

Hello ! how much does the whole project cost?

4.5 million dollars

1000 dollars bro

Roughly 600€ for me. :)

Around 750 dlls for me

You are great...thank for video

If you mounted the motors in the front of the machine, would it still be necessary to take the ball screw nut off and change it's direction?

Would there be any advantage of placing the ‘y’ axis sliders horizontally on top of the c-section rather than on the outside?

Looks like you forgot to post the link for the printed part to remove the ball screws.

You Da Man...way to go bro!!

Very Good, God Bless You............

Thats very good build, once this is done and plans are out there i wil probably use it to build my big cnc i have the parts for im likeing the design..

Dobra robota i oczywiście działaj dalej :). Mała uwaga... przykręć wszystkie śruby mocujące prowadnice liniowe.

Без молотка ни одна техника не собирается)))

Super just bought the book :-) many “professional” companies doesn’t provide such a quality of documentation!

Only one question: Whats the netto work-area?

Now i have to choose from 4 designs Printcnc, mpcnc, the one from miranda… and yours…

Thanks a lot! Usable working area is 520x400x115mm, of course by using longer profiles, linear rails and ballscrews you can build it bigger :) Good luck with the build!

hello, i have one question about that: why you don't use 1 motor X axis replace of 2 motor for X axis?

3D printed parts - they are from PLA, or other material?

I think you could have used two linear rails each side for the longest axis. It would give more stability.

Nice bro, I am your fan :)

Seems like you need another part to hold the ballscrews the steppers have normal bearings that shouldn’t be loaded in a perpendicular axis.

Why did you order the steel parts instead of making them in aluminium on the Dremel CNC?

Does it make a difference if it is steel or aluminium?

I had the same doubt too

Probably the minidremel is not enough precise and sturdy for milling steel and aluminium is lighter but more "wobbly" than steel.

For the same rigidity you must have more thickness and it is a lot expensive than steel

I'm pretty sure that's for the same reason for which the ball screws aren't properly supported and thus the motors won't last very long (guest why that is). And I'm also pretty sure that since the entire frame is made out of aluminium extrusions, it wouldn't make any difference if all the steel parts were made out of decent plywood, leave alone aluminium, as far as rigidness of the machine goes.

Hans Olo why are you so negative?

For his age and limited experience the design is pretty good.

He will learn and eventually add bearing block with thrust bearing when the bearings in the motor wear out.

There is nothing wrong with Aluminium frame as long as the forces acing on it are below the tensile strength of the profiles he is using.

He is learning. He will discover the weak points and his next version will likely be more rigid.

What he is doing is much better that guys they watch UA-cam videos and criticize but never actually build anything.

I have dilematic about the design, and yes this design is a common cnc. Take a look at 5:50 see how the aluminium gantry bend.. it stressing the structure and bearing block. I like to asemble that part 1st, and then the aluminium table

Tell me please, how much did the whole construction cost?

Very nice project made with very top components balls screw and linear ball bearings very sturdy structure and interesting motor drivers go ahead that i'll follow you. Maybe the ball screw in between by blue plate and chassis for a better protection of the lead thread or will you make some kind of protection, like a carter?

Hi, to the next video!

It seems wierd that you dont have a bk orf fk support for the ballscrew. The point of ballscrews is to remove backlash but there is nothing holding the ballscrew from moving along it´s axis. You should really fix some thrust bearing for the ballscrews

I just ordered a 3018 mostly for cutting aluminum, how do you think this compares to a 3018?

I've purchased the majority of the parts you have listed on you site which now have arrived and I've tried to assembly the rails onto the profiles. The M5 nuts seem to fit the extrusion correctly but the conterbores in the slides are to small to take an M5 capscrew. I've also tried the M3 nuts which fit the slides but because the nuts are a little smaller they keep turning in the form and become unclammped. I would appreciate if you could tell me what I'm doing wrong as your videos make assembly look quite easy

Cool project, thank for sharing your work !

9:15 - you dont need to grind that small pieces - just use flat screwdriver to break them out.

Nice but you need a fixed bearing block. A Motor shaft isnt able to handle axial loads for a long time. 👌😉

I really like this design. I was wondering though why you used steel for the connecting plates rather than aluminum which the profiles are made of. Also, what type of filament are you using for your 3D printed parts. I suspect either ABS or PETG.

Those couplers can not resist axial load. How are you indexing the ballscrews? What stops them from slipping along their axis? Anyway, great project. :-)

Awesome project !! I see that you don’t have any kind of thrust bearing on either side of the ball screw, that might be an issue when cutting loads get too high. Bardzo fajny projekt jak skończysz to też sobie zbuduje!!

Możesz rozwinąć swoją wypowiedź. Rozważam budowę podobnego. O jakie podparcie chodzi?

Nice Project. I like the Open Source approach.

As Said before, you absolutely Need a at least a fixed bearing on the side of the motor. Its ok ( Even advantageous due to thermal expansion) to leave the other side floating. Your Problem will be the reactional forces ( when your gantry is moving in y-) away from the Motor along the ballscrew. They will simply pull appart your couplers if the ballscrew isnt fixed in position.

Are you planing to install limit switches? They are nessecary to archieve repeatable machine-Coordinates. If you are Interessed, i could send you some...

What Kind of spindle are you planing to use ?

Great work Nikodem! Is this CNC powerful enough for cutting carbon fiber?

yes it is :)