Visual Management (Types of Lean Visual Management You Can Use)

Вставка

- Опубліковано 25 жов 2021

- Join our list for free Lean Resources: emsstrategies.com/newsletters...

Lean Visual Management. What is Visual Management? What is a Visual Control. In this video, we talk about the two types of visual management and offer a few examples of each. Opex Minute 41 Presented by EMS Consulting Group, Inc.:

www.emsstrategies.com

#opexminute #visualmanagement #kaizen #leanmanufacturing #leanmanufacturingmanagement #leanmanagement #5s #kanban

Welcome to today’s edition of the OpEx Minute, presented by EMS Consulting Group. Today we will be talking about Visual Management.

In a previous OPEX minute, we talked about 5S, which is a system for creating and maintaining a visual workplace: • Video Today, we are talking about visual management in general.

What is visual management and why is it important? In Jeffrey Liker’s The Toyota Way, there are 14 principles that he identifies. The idea of visual management is a big part of several of these principles. Visual management includes 2 basic forms: Visual Controls and Visual Displays. Visual Displays communicate important information, but do not control what people or machines do. 5S Visual Workplace falls mostly under Visual Displays. Visual Controls communicate information so that activities are performed according to standards.

Let’s look at some examples of each. Beginning with Visual Displays. Visual Displays can include 5S elements such as shadowboards with outlines for identifying where tools or other items might be placed. They also include things like Metrics Displays. These communicate performance measurements to target.

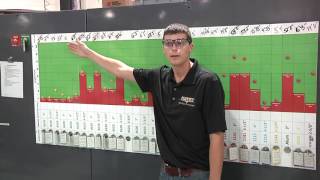

Visual controls actually ensure that activities are performed correctly. For example, you might have a process control board that displays planned versus actual production. This board has a Red/Yellow/Green System that is used for moving folks around to ensure that production is brought back to standard. Another visual control is a mistake proofing device that prevents production or another activity from proceeding unless certain conditions are met. Finally, Kanban and FIFO lanes are both examples of visual controls. They control the flow of work and the amount of inventory.

Visual Management is critically important to a Lean Transformation. If you have an interest in learning more about visual management, visit our website at www.emsstrategies.com and contact us. We would be happy to help.