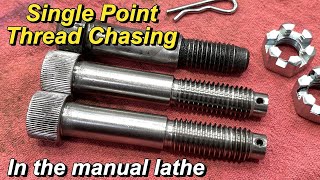

Catching up on a thread that was dismounted from the chuck

Вставка

- Опубліковано 26 тра 2015

- In this episode, I'll show how to get back on your feet after you lost the thread on a single point threading operation, for any valid reason or excuse...

Hope you enjoy, for any questions, just leave it in the comments, and, I'll get back to you as soon as possible.

Thanks for watching and feel free to like, comment and please subscribe for more content... - Навчання та стиль

Hey Pierre , I liked your video very most and I watched many on this subject. Yours was the best.

Wow, thanks!

It's alway rewarding to hear some viewer that liked the efforts a creator put into making a instructive video.... 😊👍

7 years later by now. Nevertheless, thinking a little and watching... Yes, this is the way to do it. But not easy on very fine threads like 51 TPI (in metric 0.5 mm). Imagine a well know Tuber tried to show this but did it wrong!..... Thanks for the video.

You're right about finer threads, it works better if you have more material to remove than if you're very close to finishing. Being experience and meticulous will greatly help in this and other very delicate machining situations.

Thanks for your comment...

Cheers,

Pierre

Well done Pierre. Thanks for the video.

cerberus Hi Harold, good to have you visiting, thanks for comment, Pierre

Thanks for taking the time to show this Pierre .

Cheers

Martin

You're welcome and thank you for your comment, Pierre

Excellent tutorial. Very useful for me. Thanks for sharing.

Jim Milne Hi Jim, you're welcome and thanks for the comment, Pierre

you made that look easy Pierre, Im sure it will be helpful to many people

Bravo!

See you tomorrow, I will handcuff the suitcase with the parts in it tomorrow morning

Phil's Projects See you tomorrow, and re-tracking is not so hard once you've done it once...

Pierre

Well done. Those are some quick hands you have there.

Joel L Hello Joel, the first times I threaded it wasn't that fast......!!!! I was much more nervous and sweating.... lol Practicing makes better and builds confidence.

Thanks for comment, Pierre

Very nice !! excellent thread

Hi, Thanks for a viewing and for taking some time to leave a nice comment, Pierre

Thank you. Very useful

Glad it was helpful!

Loved it. Great lesson. A lot of folks don't know how to do that ;)

BasementShopGuy Hi Brad, it only takes someone to show you once and a little practice...

Cheers, PIerre

Good information and a Nice edit! By the way, I showed my wife your "cleaning with alcohol" segment. She has been using the technic around the house now. I'm not sure the house is cleaner, but she's happier! lol

Wide Vision Metal Fab Hi Matthew, first goal in life is to be happy.... Much obliged! Thanks for comment, Pierre

Hi Pierre. Ahhh - I well recall the first time I had to recover a thread! Truly it is not as scary as some think. Mind you, always found it easier to do on a big thread compared with a really fine pitch. Enjoyable to watch that Pierre - nice close-up work. :).

ChrisB257 Hello Chris, Also easier to make a "Show how" on a big thread too... lol

Once you've done it, the confidence builds quickly...

Thanks for encouragement, I'm trying hard to improve content, filming and editing.

Cheers, Pierre

pierre beaudry Finer threads just need a better magnifying glass (or a loupe).

These days I need a magnifying glass even for the big threads.

Peter W. Meek

I feel lucky, the sight isn't too bad, but now I'm starting to worry cause I'm having problems with 120 TPI threads... lol

excellent thread :)

+Vilson Alba glad you like, thanks, Pierre

Thanks Pierre, nice demo.

rfnoise Allo Robert, demain Philippe vient travailler avec moi sur l'outil pour le coffre à Keith. écrit en français ça reste un peu plus secret... lol Questufadeuxmains???

Pierre

pierre beaudry Mort de rire.

Vien faire un tour Robert si tu peut/veux

Phil's Projects

Code secret... Les Allemands appelaient ça ENIGMA....

Good review on this process. I don't mind doing outside threads but I hate trying to pick up inside threads since they are so hard to see.

bcbloc02 Hi Brian, you're absolutely right about the inside thread catching... Wonder how I could place the camera to show inside... ??? Pierre

Good practice to do that once in a while. You did a great how-to. Quick draw on the handle and not even a nick on the shoulder... ;-)

Colin

***** Hi Colin, wasn't that brave on my first threading experiences..... :-O

Just between you and me, there are times where I fucked up a little.... But Shuuut don't mention it here.... lol

BTW, how did the Kubota survived this shitty winter?

Cheers, Pierre

pierre beaudry

Oh everyone has a little faux pas every once in a while...LOL.

I'm just glad winter is over...Kubota's fine, me not so much.... ;-)

*****

Hey, what's up...???

pierre beaudry

Heh, Sorry I guess my comment was leading... nothing terrible, just business.. ;-)

Wish you only the best....! Pierre

Hi,

That's good information, thank you.

On my lathe, I do not have a threading dial, so I do not disengage the half nuts.

Then reverse the lathe, back to the starting point.

All the best Adam

This "backing -up" method is also good for a worn machine, it minimizes the backlash effects...

When done with care you can catch-up even with only a few thousand left to reach, be careful with taking proper care of back-lash, though... ;)

Hi Pierre, very nice thread finishing! This inserts (HSS) are the best for manual threading, but unfortunately many manufacturers are not producing them anymore! Most of the manufactures now only producing for CNC industry (carbon inserts)which are not working as good as HSS for manual threading. The business of HSS inserts is not enough for them, so they stop, and now very hard to buy them! Sumitomo use to make good ones, but they stop the production too...unfortunately

Sounds like you think those inserts are HSS, actually those are carbide inserts, at first I remember busting the tips of those at very high rate..... Like one complete insert in sometimes less than 10 minutes, now, the same edge will last ma a real long time, there is a video where I cut threads at 650 rpms in hardened 4340 steel within 3 or 4 passes, the whole process for 30 threads only needed one edge and could cut quite more...

Ref for the video: ua-cam.com/video/i4xFzmjR_XM/v-deo.html

Thanks for your comment, Pierre

Thank you for the info, I really thought they were HSS, as my inserts are gold colour too. I would like to ask if you can send me the code of those carbon inserts, as I do sometimes threading on harder materials as well.

Those are the external counterpart for the internal ones used in the video, they should do the work quite well, sometimes I'll just round the tip a little, this helps to make them less prone to break on the very tip...

10pcs 16ER AG60 Carbide Threading Inserts Turning Tool: ( 16ER for external and 16IR for internal )

goo.gl/55EPku

Hi Pierre, many thanks again, how do you grain the carbon tip, what stone you use? Does it not effect the thread quality regarding (rocking/wobbling) ? Any possibility to have your e-mail?

Use a fine diamond file, with a grain like 500 to 1000 grit. It's ok to have a radius on the tip, the coarser the thread the bigger the radius, if you have a "Machinery's Handbook" or a similar reference, it's all described there.

No problem for the Email:

wledpierre@gmail.com

If you don't get a feedback in a reasonnable time, just let me know here so I check if it wasn't blocked...

does your lathe automatically disengage while threading? that looked really close margin of error on the shoulder

meocats There is a production bar on this lathe, but never used it, by these times I'm the "automatic", at10 TPI the shoulder is coming fast, but it's manageable up to about 500 rpm on a angled half inch thick shoulder like here.

Thanks for comment, Pierre

like it thanks

Ed Ginsberg Thanks for comment, Pierre

In this episode, I'll show how to get back on your feet after you lost the thread on a single point threading operation, for any valid reason or excuse...

Sir .pls the name of this method?

There isn't a specific name for this, just the procedure on how to get back in the original thread and continue the threading....

Thread chaseing

If you do much repair work you will do this a couple of times a week. The usual cause is some idiot hit the end of a threaded shaft with a hammer and damaged the threads when doing a disassembly. Welding up the damaged area and picking up the thread to recut the the ruined threads is the usual cure.

With a little practice it's easy to get back in the original thread, this is a video meant to beginers and/or amateurs that cold hesitate before dismounting or undergo a repair like you mention...

Thanks for comment, Pierre

You missed lubricating

This is for a demenstration purpose, lube will impair visibility and clarity, I normally lube when threading... ;)

Thanks for viewing and for your comment, Pierre