Це відео не доступне.

Перепрошуємо.

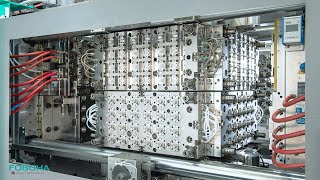

6 Tips to install Plastic Injection Mould on Molding Machine

Вставка

- Опубліковано 16 сер 2024

- 1.First of all, a pre-inspection of the Plastic Injection mold should be carried out before installation: the pre-inspection is to check the mould quality and repair the mold in time, to avoid disassembly the mould from injection molding machine. we should pay attention to the direction and the mark of fixed plate and the moving plate, to reduce errors when mould close.

2.Pay attention to the installation of the Plastic Injection Mold with a lateral parting mechanism: If there is a die with a lateral parting mechanism, the slider should be installed in a horizontal position because the sliders moves left and right, so it must be in a horizontal position.

3. Plastic Injection Mold must be fastened: When we install the locating ring to the seat of the fixed Platen on the injection molding machine,Move the Clamping Platen slowly and clamp mould gently, There should install 4 pieces of gasket on Clamping platen, and the screw height adjusted to the same height as the mould leg. It means screw and mould leg is flat, because the mould can’t be pressed very tightly if the clamping plate is not flat or inclined.

4.Connect the cooling water, and check if the water going smooth or any leaking.

5.After the Injection Mold tool is installed, a correction should be made to the ejector rod, including the ejection distance: after the mold is tightened, Mould slowly opened until the moving plate stops to retreat. Here is the position of the ejector rod, there should be a more than 5mm gap between the ejector plate and bottom plate , which not only prevents the damage of the mold, but also ejects the parts.

6.The tightness should be adjusted when close mould: adjust tightness is to prevent overflow, and also to ensure proper exhaust of the mold cavity.

Hi,This is daisy, if you have any questions or suggestions about this video or Plastic injection mould, welcome to share your comment or send me by mail:market@rdmould.com

Whatsapp:+8613105612661

linkedin: / daisy-lee-2769b684

Subscribe me!

I am a senior technician in electromechanical industrial maintenance with 5 years of experience in plastic injection. (28 years old).

Hate return springs! Tie the ejectors with a good quality bolt and thread lock

No torque on the clamps? Barb fittings with no hose clamps? no leveling of the tool? knockout bars? or hydraulic eject?

Those cores look like they had “fountains” and they looped the external hose which caused the flow in one of them to be back wards. 68 yr old mold maker here. That is what you get on the floor when they don’t understand how things work.

good

Damn, if this your standard in 2020....its like middle Ages.

Super Super no word to say all die is very very good 👌👌👌👌👌

Thanks Shailesh

A apretado más las bridas de la parte fija que las de la móvil, en la parte móvil no descansa la placa como en la fija que se a apoya en el centrador y las gomas del aire están puesta solo a presión humana, unas bridas seria mejor para apretar, dos fallos gordos

I love this job, it's good

Please also show a movie about the clock of the injection clamp

Perfeito 👏👏

I did injection molding for 25 years and never pushed pipe onto a fitting like that 😳

Best video for learner.......

Thanks Shashank

Id like to have seen more clamps on fixed half! was there only 2? or 3? Some jubilee clips on the water fittings and a decent eyebolt that's not made of cheese. Preferably the cores shouldn't work with the guards open.

This is what I do except this mold is like 1/8th the size of our smallest mold

3300 tons is the biggest press at my place

Very useful thank you

my pleasure

Molde funcionando com porta aberta sem chance 😢

Great 👍

No centering plate on the moving half? Dangerous!

moving doesn't need to be centered.. I did notice that he didn't level the mold which is 100x worse.. as long as your platen is level and your press is level you should only need a stationary centering plate.. your stationary side is in place correctly it'll be center under tonnage after leveling of course.

@@mikefishes6232 If the mold is fixed with screws through holes, it is not absolutely necessary to center the moving half. Here is fastened with claws! So half of it is only held by friction. Then there is always the danger that half will slip down without being centered!

@@HarzerLausbub-orginal oh okay, we have moving halfs on rotary tables that get clamped on and direct through hole when possible and we run into no issue but I hear you.. I think our moving ones actually have 4 studs that go into the table for added support

6:40 Hi can you please guide me what are these bolted inserts in the plate for? What is their use because i have seen several molds having completely solid plate but some molds have these inserts bolted in tha plate so what is the purpose of this?

Explain about mould tonnage setting

The Injection molding machine is 250T Haitian

@@daisylee8413 is there electric motor attached for movement of sliders?

@@ramand6490 it's hydraulic cylinder

when i see how the hoses are laid and the water is pissing out of them, i feel sick

cool

後面安全門不用關就能關模?

Goood work 👌👌👌👌👌

Can we use d/nt moulds on one machine like changing the mold

sure

What is yhe name of this machine

Are the workers unionized?

Ionized?

im nepali now im work in malasiya jhor baru same ppi

mold sathing im find job

8 water leak clean ups later we have 8 parts.

Ok

Where is Retaining pin ?

А вот нахуй шпанайзеры нахрест переставлять не понял ... Представлявляю, что они там после обеда по пьяне чудят )))