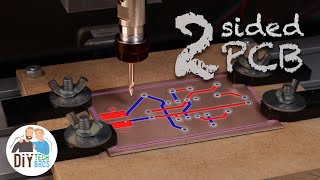

#46 PCB Milling with a Chinese CNC 6040 and some Tricks

Вставка

- Опубліковано 4 жов 2024

- In this video I show you my tool chain to produce prototype PCBs. It starts with Eagle, continues with PCB-Gcode, GCode-Wizzard and Autoleveller. The whole thing is held together with a small java program written by myself.

You find this program on Github: github.com/Sen...

PCB-Gcode for Eagle: pcbgcode.org/

PCB-Gcode Wizzard: www.pcbgcode.com

Autoleveller: www.autolevelle...

never mind ur accent. u are very clear and honest with opinion .god guide and bless u. great video sir.

Thanks!

I know this might sound a little odd but I find his accent and voice to be quite relaxing and easy to listen to. He certainly knows his stuff and I always find myself on his channel when I'm researching. :)

Just bought for amazzing price bit.ly/2GM4tkO

We like good prices :)

ua-cam.com/video/oGfYQXd-7vc/v-deo.html

This channel is full of hidden gems. This CNC setup is awsome.

Unfortunately, this machine is sold in the meantime...

Thanks for your detailed commentary on the PCB milling...

You are welcome!

come from a cnc programmer operator for many years, i'm still learning alot from your video. i appreciate your works and teaching.

Thank you for your nice words!

THANK YOU ANDREAS! (From a patron) I plan to duplicate this in my home lab.

Enjoy! I do no more mill my PCBs. They are so cheap from China...

Great video. Just happens PCB milling is something I'm looking into right now.

:-)

July 1st Canada Day 2020- Just ordered a CNC from Amazon. Trying to get my head around the process before i start making my pcb. Thanks.

Good luck! I stopped making PCBs because of the cheap and high quality PCBs from China. They are double sided, too

This is a great video. Thanks for doing this. Amazing effort and techniques. Great accent too. I also like the feature of this system being able to achieve surface mount pcb.

Thanks for your nice words!

Andreas, very interesting and informative material. I've been considering getting one of those Chinese mills and I think you've finally convinced me! Take care!

Thanks!

Wow. It is my first video of how to make thise milled prints. Good work as usually :-)

+Asger Vestbjerg Thanks!

That's very interesting, but also very hard. I make PCB with photo procedure with much less sweat&tears :)

Great work once again!

fbonacic if it is working, it is no more too complex. Jost till it worked ;-)

One more question. What is the type of spindle motor: brushed DC or

brushless (BLDC) motor? I'm considering buying this cnc, but don't like

idea of brushed DC motor..

And is 800W enough to mill aluminum, or it needs 1.5kW?

Thanks!

I do not know. I bought it including the power electronics for the steppers and the spindle (blue box). I wanted a working machine to start with...

Mine is 2.2kW, which is usually too much. So, unfortunately, I also cannot answer this question. However, I think, 800W is not a lot. It also depends, if you use 3 or 6 mm mills. Aluminium is already quit hard.

I also do mine using laser printer transfer etch technique even though I have my DIY (home made CNC from scrap materials). I love doing the conventional way. cheers!

Thank you for showing us that Auto-Leveler tool!

I've been doing this for a number of years now, and it's the Z-Axis variations in PCB thickness that causes me the most trouble. It's not my machine, it's the FR4 of the PCB material that varies every so slightly. I'm hoping this Z-Mapping feature helps.

It should help. I sold my machine because I get now 2 sided PCBs for a few dollars from China...

Always inspirational, Andreas.

I'm in awe of you!

Considering that English is not your first language you are Very easy to understand.

Thanks for the compliments! No need for such things. I just lived a curious live :-)

Appreciate your sharing and clear guide.

:-)

This week I started designing a CNC in sketchup, I was also thinking about an auto leveling system using tactile measurement. Your video just gave me a nice tip ;)

+Sven Troncquo I think, tactile autolevelling is not easy (at least, I do not know, how it can be achieved at 10 - 30 points over the whole copper plate.

Autolevelling using the conductivity of the top of the copper surface is a piece of cacke.

As you might have seen I also use also a copper plate to level the z axis for normal milling jobs. It is simple and very precise. The only thing I did was to build a small circuit to extend the first contact. This means, that, if the mill is coming down I want to stop it right after the very first touch. This touch often was too short and was not recognized by Mach3. This is why I extend it to about .5 sec (of course with an ATtiny85). Like that, Mach3 registers already the first touch.

You may want to look at Diptrace for schematic layout, and CopperCam for G-Code generation. I replaced Mach3 and the Parallel port, with bCNC running GRBL (on arduino of course). Having to using a Parallel port is kind of a hassle for me. CopperCam has it's quirks but it is very simplistic and easy to use; including making simple changes to traces before you generate G-code.

So you use a completely different tool chain. I decided to keep mine as long as possible, because it works, and it was quite a lot of work to get it,there.

I do not touch the PC with Mach, and it is still on Windows 7.;-)

Just came across your video. Funny to see that you almost exactly ended up with the same hardware AND software choices as I did. Results are very similar. Only differences I have in my workflow: I do not use the gcode wizard but instead use a software called opti_qt.exe ( free and from one of the sources for pcb-gcode) which sorts all the moves and maximizes the efficiency. Only trick you need to know is that it requires the gcode with fileextension *.nc. I have also programmed a autoleveller but in the end decided to increase the DRC settings (min wire size to 20mils) and set etch depth -0.2 This way I get consistently very good results but only for through hole designs. If I need smaller wire size with SMD I switch to photochemical process.

Because these days manufactured PCBs are so cheap, I do not do many for myself anymore. I just order them with silk screen etc.

Thanks for Autoleveller!

You are welcome!

Useful tips about the software! thanks!

:-)

Where can I buy one of those Swiss accents? It sounds great.

And, on your videos, I especially appreciate - your commentary is not competing with loud music. If only all UA-cam videos were like yours.

I have the same opinion about music in videos. Maybe the younger generation thinks, content alone is boring and adds music...

Wow Awesome video Thank you for sharing

You are welcome!

Nice video! I personally now use CNC 30x40 to make PCBs (1 & 2 sided). Been through a lot of software already and here I could recommend you Flatcam - much more easier to use to generate gcode as you need.

Do you use Eagle to draw your diagrams?

Yes - I start all my projects in EagleCad - once completed move them to Flatcam and then to assure pefrect leveling I use AutoLeveler which adjusts heights to differential heights on my PCBs.

Also I'm working on improving flatcam to support easier 2 sided PCBs without need for allignment holes etc

Sounds interesting. I do not do any 2 sides PCBs so far. I do tnem single sided and, after debugging the diagram, I just create a double sided board and send it to Osh Park...

Well this method using this software combo has realy potential ;) suggest trying that out - makes life so easier

Great video. Thanks

You're welcome!

I'm an electronics engineer, I am taking the plunge and buying a CNC Mill for PCB work. I've been looking for one with auto levelling but no success yet. How do you get yours to auto level? I don''t mean software, your explanation on software is well covered in this video. I mean the electrical connections to the controller? The cheap ones are well documented but the bigger more expensive ones with external controllers are harder to find this information.

Thank you

I do not use it anymore for PCB, because you get so cheaply made PCBs. And creating 2 layered PCBs is not easy, especially the vias.

Auto-leveling is done with software. You connect one pin to the spindle and one to the (isolated)PCB. The software moves across the copper and goes up-and-down. As soon as the tool touches the surface the pin goes low and the software knows the hight.

Andrew, I think the setup uses the same connections as the automatic Z height setting block. Rather than the wires connecting to the tool and the block, they connect to the tool and the PCB surface.

Sutch a great video! Congratulation and thank you!

Did you do the dedicated video to the cnc improovement and capabilities?

I plan to buy one, and to do the same modifications as you.

Thanks!

No, I never did it, because the interest for this video was not very big.

Hello Andreas

at 0:41 on the right side there is an aquarium pump or pump that comes with cnc?

Or i must buy pump by myself? Pump is not included with cnc?

Thanks, like and subscribed You have interesting videos, i love electronics stuff

It did not come with the CNC

Really nice job Andreas,and i'm intrested a lot in to your "home" milling machine.

You did more videos about?

No, And I hardly use it anymore since I have my 3D printer and cheap PCBs from China.

@@AndreasSpiess hmmmm......maybe we can have a deal ?

I would recommend FlatCam it is a better cam program and is free

Thanks for the tip. For the moment, I have my "tool chain" set-up and I invested quite some time to make it run. But for somebody starting now, this is for sure a good idea.

Im very inspired by your videos thanks a lot :).

If I would like to have the same setup (cnc and so on) would you then bedre kind and give me a list with links on were to buy the participation cnc machine and tools (cutting and so on)

With lead times to get anything from China becoming very long because of the virus (Spring 2020), being able to produce a board quickly in the lab is becoming very desirable.

What kinds of lead times are you seeing in Switzerland and have you considered doing boards in your lab again?

I rarely use home grown PCBs. DHL still works fine from China. More expensive, but it worked in my case.

@@AndreasSpiess Thank you for responding. Glad to hear you can still get boards turned around quickly.

your english I understand it very well congratulations for your video

Thank you!

Thanks Andreas, very informative. Would Auto Leveller work with a GRBL CNC like my little Chinese 3018?

I do not know. It injects a lot of commands in the file for the CNC. Mach3 is able to read it.

@@AndreasSpiess Should be fine then, thanks Andreas.

What if you use a non v-shaped milling tool. Would it help prevent the copper from being removed if the cnc cuts too deep?

I'm noob with cnc machines.

Woooow, the autolevelling trick is exactlly something I was looking for. Thank you very much.

You would need very thin tools, and they break very, very easily. So, the V shape is a good compromise.

The pcb-gcode wizard is on a site that requires you to add an extension to chrome. Sorry but I do not like to add things to my browser unnessarialy.

This is an old video and the CNC was sold last month. So I do not know the latest status.

Oh man, very nice tutorial. I have only problems when a heard C axis. Actually it is Z axis :D

As far as I know, Z is spoken like C in American English

As you can hear here: dictionary.cambridge.org/pronunciation/english/z-z

Its pronounced as british "Zed" and american "Zi:"

I have friend from Vienna, who said, that he has file with .cip extension. It was actually .zip :)Not a big deal, it only take few minutes to realize which way german pronounces. Anyway, very nice tutorial!

Sehr gut. The link of the PCB-Gcode Wizzard is not working now, they may be updating the site.

You are right. It is not there anymore. I have no clue, why.

great video as usual . when you use your vacuum table , is see you dont block most of the unused holes. Is that just something i missed or there usually enough vacuum . i can see how a few open near the work piece helps remove dust . Only asking as other such hold downs i have use using a shop vac , required us to place paper or such over the unused parts of the table to increase the hold down effect on parts.

+XerotoLabs You are right! Usually I put some papers around the PCB. Because of the filming, I forgot them and discovered it only during editing.

The dust does not go into the holes, because they are much smaller than they look like. I made them in two parts: On top, bigger and the bottom half only about .8mm. I did this because I thought, with this principle, I do not need the trick with the paper. But this assumption was wrong.

For the dust I have plexiglas at both sides and a flexoble plastic at the back of the CNC. So, it remains more or less on the machine itself. But, A CNC is not a clean machine and the dust is everywhere and the whole room has to be cleaned from time to time.

Great video for those with a machine like yours. I watched with envy. What happened to the weird track routing on pin-7 of the ATTTiny? Were you drinking schnapps at the time :)

+Graham Gillett You are a very good observer! The autorouter probably had some schnaps... I still struggle sometimes with the aoutrouting function of Eagle. If the grids are somehow not in sync it does some weird routing (only since the latest update). Because it is a prototype I did not care, but usually I correct it manually. I have to take some time to find the root cause and remove it.

It looks like you are going a bit too deep in your engraving, in my experience you only need to go 0.05mm deep. I have a few vids on my channel if you are interested

I do no more create my own PCBs. The Chinese manufacturers are very attractive...

@@AndreasSpiess Agree, having PCBs manufactured is very cheap these day, usually the shipping is more than the cost of the boards themselves. But it's hard to beat the convenience of being able to make your own prototype board in a few hours especially if you need several revisions to get the design just right.

Hello

I would like to share my experience of PCB design with CNC. I am using CNC 3018 machine.

Fist I design PCB using Eagle or Proteus with clearance of paths and pads according to V bit diameter. After that I export it to gerber files using CAM process.

These garber files open in Flatcam software and generate G Code files. Faltcam software is very good software and it is free.

Then these g code files open in bCNC software. It is python base software and it is use for auto leveling and mill the PCB. CNC 3018 machine can use GND and A5 pins for probe to auto leveling. I connect A5 to V bit and GND connect to PCB board.

Before I mill the PCB I decried whether ferric chloride is use or not. If I use it, then I paint on PCB board using permanent marker then I can remove non milled copper. If I am not using it, I setting up Z axis little bit more depth.

Then I can get perfect PCB.

Eagle or Proteus --> Flatcam ---> bCNC ----> PCB milling

Flatcam (Free) - flatcam.org/

bCNC (Free) - github.com/vlachoudis/bCNC , ua-cam.com/video/Z59BkvBOx5A/v-deo.html

V Bit Groove Dimension Tables - bitbucket.org/jpcgt/flatcam/wiki/V-Shaped_bits__Groove_Dimension_Tables

Thank you for share your knowledge and experience with us. I really like your channel. I know that this types of video can not make easier. You should spend lot of time to get experience of it. I appreciate that and thank you very much.

I would like to suggest make new antenna videos. How to choose antenna according to frequency and what should be the features and specifications like length, width and so on.

Thank you for your report. Very interesting.

Concerning antennas. I have many other topics an there are other channels covering antennas in detail.

Would you have preferred to invest in a chemical pcb manufacturing process? Or are you happier you have a milling station.

+Glychee S I did the chemical process and did not like it. Maybe because I am an engineer and not a chemist ,-)

And in addition, with milling, I have the holes drilled and the milling around the PCB in the same step. But of course, the effort is bigger and the equipment is more expensive.

I never knew you had one of these. Do you still have it?

No. I sold it a few years ago. I did no more use it when I got a 3D printer.

@@AndreasSpiess it was pretty cool though. Have a few printers but I'd like a mini cnc for making pcbs. Just small ones for making light effects using a pic and a string of leds. I have an led obsession haha I'll never have as many as big c even though I've gotta be over 100K now of all different types haha

Hi Andreas, great video. just to double check... the etch file is used to cut the trace and the mill file is used to cut out the board profile?

Yes. The mill file is super simple and short.

Wonderful video ;)

What happened to your nail? (last few seconds of this video). CNC accident ? :)

Great channel!

+Felix's Lab no, no.

I hope it's fine now ;)

Quick question. I'm about to buy my first CNC machine and I found this one:

www.olx.pl/oferta/frezarka-cnc-grawerka-510x310x45-zobacz-film-CID619-IDdSxYF.html#3ee7f654fc

It has trapezoidal screws.

Do you think it's worth buying or should I look for chinese 3040 with ball screws?

I would like to use it for CNC PCBs and some slow aluminum milling.

The movement motors are half the size of the ones used in my machine. So, I am not sure it will be able to properly cut aluminium (this needs quite some power, independent of the size of the machine if you do not want to lose steps). PCBs should not be a problem.

Thanks Andrea for sharing your process, what angle V-Bit are you using?

I use 10, 20, and sometimes also 30 degrees. I cannot tell you which are really better because I did not do a formal test. The smaller, the easier it is to set the z-axis height. But they might wear out faster.

May I ask what spindle speeds you use for milling the traces? Also the model of your spindle? Thanks.

I use the maximum speed of the spindle(20000 rpm). My spindle is a chinese 2.2kW.

Thanks very much.

Hi there, couldn't help but notice the PCB was moving whilst it was being milled. Might I suggest using double sided tape for holding a PCB down?

I used a vacuum table and usually, it did not move. These days I do no more mill my own PCBs because I can get them very cheap online.

Du musst die restlichen löcher vom vakuum tisch mit papier abdecken, dann hält er die platiene viel stärker

Mach ich. Nur nicht im Video. Vergessen ;-)

Nice video, but I have to say that the quality of the pcb was really bad. I use autoleveling as well, but with a 60° cutter and drill/mill the board in one step. The finished boards look really good. What do you do to solder easily and do you use solder mask?

I do no more mill my PCBS, I order them online these days.

Andreas Spiess I understand, it's cheaper than buying the fr4 plates. But still, with milling you have the finished prototype after a few minutes and can check for flaws in the design.

What a good video. You're amazing.

I have a question and I don't know if you can help me.

I have a 3040Z Chinese CNC, I want to do PCB's but I always have problems with the Z axis, WHat I need is AUTOLEVELER, but I use CNC USB CONTROLLER, because I have a laptop. I don't know if there's posibble to do autolevel if I use this software.

Thank you again!

+Marco Valbuena It creates a special G code for Mach3. Maybe you go to the homepage of autoleveller and check if he has a version for your purpose. Or you search for another software. Without autoleveller, it is not easy...

Thank you so much again

I had a similar machine, what would be good is to find how to get it upgraded for greater accuracy in x,y,z and higher speed quality spindle

So far mine was accurate enough for PCB milling. I am not a mechanical engineer :-(

Hi Andreas again Where abouts do you add Isolation around traces in Eagle that once the traces are milled the copper next to the trace is removed Cheers Benjamin

I do not exactly understand your question. Maybe "ratsnest" in Eagle is the answer

what i was Meaning was Trace isolation, sorry for the confusion so basically removing the copper around the trace

+Benjamin Isaacs I thought, I show the whole process in the video? There, you should see, which software I use for each step

Yes you do but you apply the ground plane and what i want to do is remove the excess copper as i have a PCB Antenna

+Benjamin Isaacs Now I understand. I do not know how to do that. I only could think that you mill this part the conventional way. Maybe you can do something by adding some thick traces in the milling layer.

another good video, how is there enough time for you to do so much or be so educated, would a magnet of some sort under the board help?

Thank you! I take my time and go step after step ;-)

@@AndreasSpiess thx for replying you're of the few that has replied to the many comments I have made on this UA-cam.

I try to answer all comments

@@AndreasSpiess I can't imagine what will be next???

@@AndreasSpiess I'd like to take a cheap drone cut their motors off and splice it into a homemade drone using transformers and multiple leaf blower motors with carbon fiber blades having the controller in hand, I'd like to use a tow bar from the frame with the blades to another frame that carries the weight with multiple cameras a virtual head set and for now signal relays for obstacles send it to the store and back.

Hi Andreas,

Could I ask you which CNC controller board you are using and how you are connecting your computer (USB or Parallel). I read that there are complications with using USB and autoleveller. Thank you!

Sincerely,

Tin

I use Mach3 through a parallel port. The CNC controller accepts this parallel port signals

I'm seeing Gcode for eagle would that not gonna work for Altium Designer?

Thanks buddy 👍

I do not know Altium. So I have no answer.

With your method I wonder where to connect the probes for the Auto leveler???

The probe is connected to ground and to the copper (I press a small probe during autolevelling to the top of the PCB). The tool is usually grounded, so the circuit is closed if the tool hits the copper. And this is exactyl what I intend

One irritation I have with the Gcode PCB_Gcode generates is that it seems to waste a lot of time in useless movements. For example, it will position itself over one side of the board and starts milling out in that area and then it will just suddenly stop working in that area and go totally over the other end of the board, mill out some isolated lone pad and then come back to where it was to carry on... What's the point of that? And it doesn't do it just once or twice, it constantly does it. Why not do as much as possible in one area and then move on? They say it's mathematically efficient but watching it work it seems very counter-intuitive to me. The other problem I have with it is that Tool changes are just totally mind boggling to understand or use and the manual isn't much help in that department either. So say I want to mill out a PCB but I have a variety of different drill sizes such as one size for components and another for Vias... It's a nightmare to work out so for now I just use one size drill bit for all but it's becoming impractical to do this with more complex circuits requiring small vias. I can't knock PCB Gcode for what it is but people should be aware it does have limitations and in some places a rather complex learning curve.

1. I use a software to optimize the tracks (I think, I showed it in the video)

2. I only drill with the smallest diameter and then enlarge the few holes manually. Is quite easy with an existing hole.

Hey Andreas! First off all, thank you for all your videos - they've been a real big help to me and secondly, thanks for replying!

I was milling out a panel of six breakout boards yesterday - not an easy task without auto-level (I'm still using the stock control boards in my CNC3040 so don't have auto-level yet) and your video came to mind as I watched the GCode undergo it's usual ADHD moments where it went and started a bit on one board and then before finishing it, it shot off to the other side of the board to start something else. I had to laugh to myself. I also ended up doing what you said. I drilled out all the holes at the smallest diameter and manually enlarged the rest by hand. It's not a bad approach to small boards with a few holes but on larger designs with varying sizes it could be a bit of a headache. I'm always keeping my eyes peeled for faster ways to get stuff done with as fewer tools in the chain as possible.

Why you are not using target3001? It has a gcode encoder already in by default

Because I never heard of it. But I will try it out and see, how it works and which libraries are available

I would like to have the same setup (cnc and so on) would you then bedre kind and give me a list with links on were to buy the participation cnc machine and tools (cutting and so on)

This is an old video and I do not have these links anymore.

Andreas Spiess do you have more info about it other than chinese 6040? What about spindle and spindle tools?

Hi Andreas, can you tell me more about your CNC upgrades? (i.e automatic zeroing of x and y axis, z axis). Thanks.

This is a very old video and I do not use my mill very often. I have implemented zero switches. It is supported by Mach3

Can you give me more information? thank you

Connecting the PCB to mainly GROUND causes extra capacitance and inductance!

To be avoided, unless you know what you are in for!

Thank you for the warning!

@@AndreasSpiess For instance, a trace carrying high speed data, if located between two ground-traces for its length, creates an efficient transmission-line, with its characteristic impedance *and reflections*, if not terminated correctly.

Now, this may be what you want, but most likely it will be sub optimal.

If you leave a lot of copper on a board, it is best to have it "floating".

(With low-speed circuits, such as audio, this doesn't matter.)

Hi! Can you make multilayered PCB's with this? IF yes, how many layers is the limit? Thanks!

Two layers can be done, but it is not easy, because normal 2 layered PCBs contact both layers through the holes. This is not the case if you do it yourself. So. many PCBs will not work, because your layout program assumes that they are connected.

I usually do single layered to test the circuit (the board is usually bigger) . When I found and corrected the errors, I rearrange the parts and select 2 layers. Then, I send it out to Osh Park for manufacturing.So, I get a fast prototyping and a good quality final product.

What version of windows are you using? I thought Mach required older 32bit?

+Havoc Dev I use Windows 7 on my dedicated CNC computer.

Man I love that top hat where does one get a hat like that

It is hand made in the USA

@@AndreasSpiess nice

Where in usa

www.headnhome.com/collections/top-hats/products/marlow-lt-band-hat?variant=3366084444200

Hi Andreas

I have a 3Drag setup for PCB milling and it works but when i design a board in eagle then run it though PCB-GCODE and it generates the Gcode the Gcode is always in the middle on my waste board, Is there anyway to set it up so that design goes to the bottom left corner on the CNC machine?

Cheers Benjamin

I think, your Zero Point in Eagle (a + sign) is also in the middle of your PCB. If you shift it to a edge (you have to shift the parts), it should be ok.

Okay will try that thank you so much

Hi Andreas, I can't uderstand why a pcb gcode wizard is used. is there somewhere I can get more information on its purpose? I understand it removes unnecessary moves and trace cuts but I cannot understand why or how these are generated if they are not required. Can you shed some light on this please?

The plugin in Eagle produces sometimes too much traces (for example I do not want to have traces around the PCB because I mill the PCB later. The same is with holes. So I remove these because they need quite some time to produce and wear the bit

Thanks once again Andreas.

Does PCB-Gcode work with the latest version 7 of Eagle?

I use it with 7.2.0

How do you get from 12:03 to 12:05 ? I am ignorant and thanks for the time.

I would call it "assembly" ;-)

Have you bought the 3-axes or 4-axes modell?

4 axes, but never used the 4th axis :-(

Wofür ist die 4. Achse?

Zum Drehen des zu bearbeiteten Teils

Have you checked out how nice ChiliPeppr's Eagle BRD Import is? chilipeppr.com/tinyg and then just drag in your Eagle BRD file.

+John Lauer I tried now but I saw only one side of the board. I need Mach3 files for two sides, for drilling the holes, and for milling the contour. Is there a tutorial for my current workflow (Eagle-chilliPeppr-Mach3-CNC)?

Your vacuum is not working, pcb is moving while milled which is NIGHTMARE to quality½!

You are right.

+1 and Sub for this video and that you ride a Harley! :D

Thanks for your support!

I'm using TinyG Chilipepr USB controller for my CNC3040Z-DQ. Its webbased, opensource tool. To use it, you need to do some solderwork in your CNC controller box. It took me 20 minutes to get it up and running.

It works by running a small driver app, which communicates between your CNC, computer and the website. Then u drag-drop gcode into it and start milling.

Check chilipeppr.com/

#science4kids

I watched many of these Chillipeppr videos. Good stuff. But for the moment I hardly use the mill. I 3D print most parts...

My CNC started collecitng dust when i discovered JLCPCB :P. I mean like $2 for 10 PCBs.. u gotta be kidding!

Use more double side tape. We use to have one of these types of tools 20 years ago. But they costed 30,000 dollars Australia. They had self levelling as well.

I decided to go for vacuum instead of self adhesive tape. I found it more convenient.

+Andreas Spiess as long as it works. One of my mates made a wifi antenna on one. Worked great.

Thanks