Це відео не доступне.

Перепрошуємо.

PROCESSING COPPER ORE IN KITWE ZAMBIA

Вставка

- Опубліковано 4 сер 2011

- Mopani Copper Mines

Mopani Copper Mines Plc (Mopani) is a joint venture company based in Kitwe as 95% of its operations are located there, comprising Glencore International AG (73.1%), First Quantum Minerals Ltd. (16.9%) and Zambian Consolidated Copper Mines Limited (10%). Mopani operates the Mufulira mine, smelter, concentrator and copper refinery and the Nkana mine, concentrator and cobalt plant. MCM produced 134,800 tons of copper and 2,040 tons of cobalt in 2003. MCM is investing in a number of oxide copper projects at several of its properties, including an in-situ leaching project at Mufulira and heap leaching at Nkana, and has achieved significant production increases at its underground mining operations in Kitwe and Mufulira. Copper production from internal sources was supplemented by the purchase of some 18,000 tons of copper in high-grade oxide concentrate bought from the Democratic Republic of the Congo.

Nkana Mine

Nkana mine is one of the largest in Africa, a copper mine located 1 km south-west of Kitwe. The mine is underground as well as open pit and is in operation since 1932 and has produced 6,000,000 tons of copper so far. Its reserves underground include 69,000,000 tons of grading, 16,000,000 tons of copper, and 98,000 tons of cobalt. Its resources include 126,000,000 tons of grading, 43,000,000 tons of copper, and 300,000 tons of cobalt. Copper and cobalt mineralisation occur within the ore shale. Copper mineralisation in the deposits changes from mostly chalcopyrite in the South Orebody, to chalcopyrite-bornite in the Central area and to bornite-chalcopyrite at Mindola. Cobalt occurs as carrollite and cobaltiferous pyrite in approximately equal proportions. The mine produces copper and cobalt from three sources: Mindola Shaft, Central Shaft and South Orebody Shaft. Vertical crater retreat is the predominant mining method while sublevel open-stopping and sublevel caving methods are also used. Other metallurgical facilities, under a management contract by an affiliate of the Anglo American Group, include the Nkana smelter (not owned by Mopani), acid plant (not owned by Mopani) and copper refinery (not owned by Mopani). There is extensive mine tailings around this mine.

Nkana Concentrator

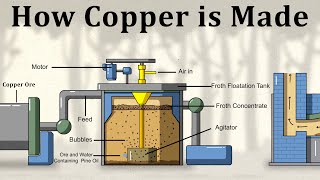

Nkana Concentrator of Mopani mines, located in Kitwe, treats copper-cobalt sulphide ore using a bulk flotation and segregation flotation flowsheet to produce separate copper and cobalt concentrates. Nkana Concentrator is the most important mineral processing unit of Mopani, as it contributes about 65% of cobalt concentrates treated at the Nkana and Chambeshi Cobalt plants to produce high purity cobalt metal.

Konkola Copper Mine

Konkola Copper Mine (KCM) is the largest copper mining company in the country. Although based in Chingola, 15% of its operations-namely Nkana Refinery, Nkana Acid Plants and Nkana Smelter (the largest smelter in the nation) -- are located in Kitwe. The Nkana Smelter is the largest primary copper production plant in Zambia. The plant treats concentrates mainly from Nkana, Nchanga, and Konkola mines, which are wholly owned by KCM to produce up to 150,000 tons of new copper.

Nkana Smelter

The smelter produces high grade anodes, which are electrolytically refined. Sulphur dioxide gas produced by the converters is converted into sulphuric acid which is then used at the Tailings Leach Plant in Nchanga for recovering oxide copper. The smelter also produces discard slag from the reverbs that is rich in cobalt which is stored for future reclamation. This smelter was part of the Konkola Copper Mine's operation at privatisation and has subsequently closed.

Nkana Refinery

The Nkana Copper Refinery produces electrolytically refined copper in the form of cathodes. The copper meets the LME premium quality grade. The tankhouse has a capacity of about 180,000 tons of finished copper per annum.

Nkana Acid Plants

There are two single contact sulphuric acid plants at Smelterco, namely the No.3 and No.4 plants. No.3, the largest, is still operational. The plant has a design capacity of 1,050 tons of acid per day.

FROM

en.wikipedia.org/wiki/Mining_i...

I lived in Kitwe as a kid,watching the slag been poured was one of our high lights. Thanks to the internet that we can relive our beautiful sights

Crazy how people are so educated to come up with this mineral in it's purest form

Nice plant.

wow im amazed

Saw some footage there from the Bethlehem steel slag dump.

i can't imagen the amount of gas and chemical solutions involve from mining to extraction to production of this minerals

ha ha, all the animated footage is stolen from the Kennecot Bingham Canyon copper mine video from the visitors center.

i can't imagen the amount of gas and chemical solutions involve from mining to extraction to production of this minerals