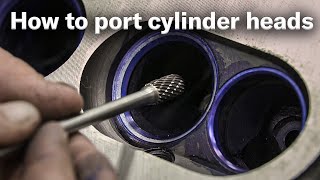

Should you Mill your Cylinder Heads?

Вставка

- Опубліковано 22 лип 2022

- Why is it important to have your cylinder heads Milled while they are off? Lets resurface them and find out...

Click my coffee link and get yourself

something to help support me.

amzn.to/2HfmkCt

amzn.to/2Q4hfA4

Or become Premium Member at My website

www.crazedperformancerepair.com/

Crazed Performance Repair UA-cam channel

Rumble

rumble.com/register/CrazedPer...

Check out my LBRY

api.lbry.com/user/refer?r=GNX...

To show some love and support me, use the support button on my website.

Automotive technician - Авто та транспорт

Gotta love an old Series One Bridgeport. Nice work👍

Great stuff 👍 thanks for sharing.

Nice video explaining the various issues. On my Vanorman 570 i have a 14 inch cutter head with 10 rotary carbide cutters. I have a .003 tip or drop in the back side of the cutter drive housing (tip the entire drive) this makes for as measured .00003 THAT IS 3 ten thousandths concave over 5 inches i am sure with your setup is much less than that. With my machine any less i get a back cut when reversing the feed table as the head is stationary, and the entire drive assembly is what is moving.

As for finish Depending on application and gasket choice you will need a finish between 80 ra (max for some felpro MLS) and 35. I know a lot of people will scream no the ra has to be lower but this is not what the OEM recommends. With some racing applications RA down into the mirror finish (sub 20) is desired. For practical application such as what this ls head is to be used on if you shoot FOR A 50 +/- 5 The finish will work well for MLS and fiber/ composite gaskets. Sub 50 will have issues fiber / composite gaskets.

Guess this is a long-winded comment saying you did it right.

Wow long winded but informative lol. I do have a .0008 tilt on the head due to deflection. But the end result is much better than any factory finish I've seen. I found out after this video if I use a different bit I end up with an even better finish. There is a aluminum specific bit that's not even carbide but it does such an excellent job on aluminum. Well so long as something didn't punch the cylinder head service from the piston lol. Found out the hard way on that one. I recently had one that had something go in the cylinder and beat up the surface of the head in the combustion chamber area. Of course every time my bit hit that it would chip the bit and cut like complete crap. Almost had to go to the carbide bit just so I can get through it. But after rotating the bit several times I did get it. Next time I see that kind of situation I will definitely be used in the carbide for the first cut. Thanks for the comment.

On overhead cam heads, such as a miata, head must be straightened if they are significantly warped then surfaced. Without straightening the head, the cams will bind.

Good point, pretty uncommon to be that warped though luckily. If they are you have to question how overheated the vehicle was.

OLÁ. Seu porta ferramenta de corte da plaina aumenta as vibrações da máquina e diminui a qualidade do corte. A regulagem da máquina está INCORRETA. No acabamento final DEVE ser visual o "CRUZAMENTO DO CORTE" ABRAÇOS... Roberto Udo Krapf

Well I always left heads alone if there wasn't a problem with head gaskets or heads to start with .. guess I need to find a better machine shop also

No safety shield is freaking me out dude

Yes

For leveling you should get a dial indicator you can put in the collet, they can be cheap and it will be a hell of a lot more accurate than a level.

Good thing I'm not using a level. I for a while use a dial indicator on the end of my fly cutter. Now I have the dial indicator you talked about.

Very cool. As a non machinist, how did you fixture the head and adjust the leveling?

I use the dial indicator on the end of my fly cutter. Now I have a dial indicator that actually mounts to the arbor of the mill.

for video that blue dye stuff they use in engineering makes for a cool video to see it cut

Just all way buy new head and check all val valve areas perfectly sealed and checked with air pressure and pass a flow bench test

And always check other people work first thing you do period

not many people have stuff to check the new heads with and if you don't trust the factory you definitely shouldn't trust aftermarket stuff. it's also cut to fit lol. best you're going to do in real life is have a local machine shop mill them and install with fingers crossed.

been my experience that aftermarket ls heads are unless going for high rpm na numbers. they are mostly waste of money for normal people with turbos. just up the boost a bit to make more power than you can put to the ground these days. freaking junk yard 300k mile 5.4. making 700hp on e85 is considered normal.

Yeah I thought about the dye thing the moment I started editing the video. Shoulda-couda-wouda right.... Lol

all machinists use blue or red Dykem

Question. Does your flycutter completely clear the cyl head at the end of the cut? It looked like you didn't have enough table length to allow the FC to clear. Now you said you needed a leading cut and a trailing cut, but if you stopped the cut before it cleared then you only did a leading cut at the end of the head. I'm just getting back into machining (and I have a short mill table) so I'm wondering if flycutting heads without a trailing cut is a huge deal or not.

Our common dedicated block and head resurfacing machines are manufactured with the tram out a couple thou as to NOT do a trailing cut. It does not create a deep dish like I have read in many comments on other videos. In fact, when set up on another machine just to dial the cut in to measure the flatness of the cut. A 0.001" dip is all I have ever measured and thats on wider heads Aluminum heads it works out fine in the end when trammed perfwctly zero, but when you get into harder cast iron heads or blocks you can run into some ugly looking back cut finishes and have to really fuss to get it consistant. Also, when doing aluminum blocks with cast iron sleeves, the back cuts tend to creat chatter. This is with machines far more rigid than a lil knee mill. I've surfaced heads on knee mills (own two myself) and it works fine, but nothing like a dedicated head resurfacing machine. My Storm Vulcans X axis saddle length has over 4 feet of table support. More than double the support of an old Bridgeport like the OP's and mine.

@@whiplashmachine Good information thankyou! I will set up my tram similarly if/when I get back into large are surfacing.

Is this head engine holding out today? I'm concerned with welding the spark plug hole shut and the machining after that may have distorted the milled gasket surface flatness

Yes, it's holding fine yet as far as I know. I'm pretty sure I milled it after the repair but I don't recall I guess. Did I say what order in the video?

My car was tuned, I messed up the heads and got them fixed/shaved I’m guessing my AFR is off? Needs a retune?

Depends on how it is messed up, however if doing a tune cause things to fail then I would absolutely say there is a tune issue. However, usually the Pistons and cylinder walls will get affected first before any cylinder had issues. So keep that in mind as you most likely damaged the bottom of the engine if you damage the top of the engine. If you paid somebody for that tune you definitely need to find a different tuner and never go back to him again. A bad tuner will cost more than any good tuner will cost in the long run. Sure the initial tune might cost more but it will save your engine.

He'll sir GMC suburban 2007 3.4 cylinder missing have i.will change coil.wire.plugs.injactor.lifters.but still same please anything another step

Check compression. Be sure to check it more then once.

👍👍👍

😂 𝙥𝙧𝙤𝙢𝙤𝙨𝙢