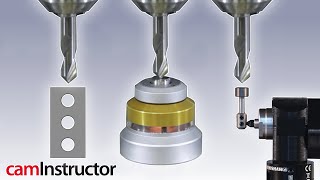

Measuring Tool Lengths on a Fanuc OM CNC Machine

Вставка

- Опубліковано 1 жов 2024

- This video shows how easy it is to measure the lengths of the tools in a CNC Mill. This is very useful for machines with tool changers that allow different cutters to be installed without doing a Z offset measurement every tool change (some CNC routers do this). Both tool numbers 1 and 3 are measured in this video. Re-doing the zero reference measurement is helpful every time because there could be some inaccuracies if the dial indicator is moved too far.

Why did you measure (or need to measure) the spindle height a second time @6:37 ? That you got a difference of 0.0015 is a bit disconcerting. Is this because you had re-positioned your tool setter and the 1,2,3 blocks ?

Hi guys! please help a newbie! I recently purchased a Fanuc Tape Drill Mate Model T CNC milling machine. I don’t know how to make the X Y axes tied, in offsets only the Z axis? Thank you!

Are you referring to tool compensation? I always put the tool diameter in the CAD before the gcode is generated. This means only that tool(bit) can be used. But I know that some people generate the gcode for the exact part dimensions so different tool sizes could be used by the same gcode.

Thanks!

Hello again! Can you tell me where the CNC Pulse Generator control panel is connected?