- 4

- 329 321

Built Different Designs

United States

Приєднався 19 гру 2023

R&D content with a emphasis on manufacturing and user interaction

Ruining my Wedding with a Bartending Robot

I saw a robot that could make drinks at a party I went to and decided that my wedding needed an engineering project. The goal was to create an over engineered robot to dispense drinks. Meeting the following requirements.

- 30 second takt time

- 4 unique drinks

- Regulates drink consumption

- I don't have to manufacture anything that touches fluid

- 30 second takt time

- 4 unique drinks

- Regulates drink consumption

- I don't have to manufacture anything that touches fluid

Переглядів: 25 720

Відео

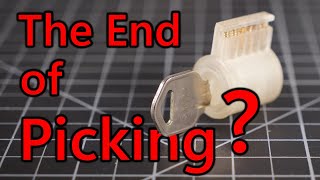

How To Pick an Unpickable Lock

Переглядів 48 тис.7 місяців тому

I will be attacking this lock using every method you and I can think of and fixing whatever I may find. This is part of a mission to make an unpickable lock to wave in the face of complacent lock companies. [1] Locksmith Ledger. (2010, March 2). Master lock meets new astm lock bumping standard. Locksmith Ledger. www.locksmithledger.com/locks/article/10228402/master-lock-meets-new-astm-lock-bump...

Manufacturing an Unpickable Lock

Переглядів 16 тис.10 місяців тому

I am on a mission to design an unpickable lock. Lock companies have become complacent, producing flawed designs. I want to make something that is not only secure but is designed with manufacturing in mind. In this video I discuss the manufacturability of the lock including manufacturing method and tolerancing. Finally, I order the metal lock and perform a demonstration.

How to Design an Unpickable Lock

Переглядів 240 тис.11 місяців тому

Welcome to an exciting journey into the world of lock design! In this video, I dissect the flaws of traditional pin and tumbler locks, exploring the vulnerabilities that make them susceptible to picking. Join me as we delve into designing a lock that addresses the challenges of both security and manufacturing head-on. Who knows? Maybe we'll end up creating something truly unpickable. The few qu...

could you make it with less precision because you would still have to get both sheer lines to open and even if you pick the inner core to turn the chance of getting the mid core sheer line would still be almost impossible :-)

As a lock picker, I have to say that your explanation and simplification of lock tolerance exploitation was spot on. Great way to explain to lay people. Good job

Awesome videos. I just found your account and i live them

that was a quick and easy demonstration of how single pin picking works.

Did you use dosing pumps? I just started the video, but dosing pumps are what you might need. Edit: You definitely should have gone with dosing pumps, you can even make them with stepper motors and 3d printed parts only requiring medical grade IV hoses and some bearings

The big thing that I found when researching peristaltic pumps is that the flow rates were somewhat low. I needed to dispense 250 ml of fluid in a few seconds. The upside, though, is the consistency of the flow rate. Hope that sheds some light on my thought process. Thanks for watching!

Not trying the picking tool u used in the beginning on your prototype at the end made me cry

i would have used Air pressure to push the fluid out of its bottles.

Everyone and his dog has a design for an 'unpickable' lock but so far they've all been picked. Unless you actually send it to a few pros to pick why even claim it's unpickable lol

Loved the 3Blue1Brown's Manim style video!

I binged all three videos. Very awesome work. I can't help but feel this may be a milestone in lock design. Your design is deceptively simple and seems like it could be mass manufactured for a very affordable price. Yes there are other lock designs that are wicked complex and virtually unpickable (Bowley lock) but they are also so expensive they will almost certainly never be sold at the local hardware store. Another unpickable lock video recently on youtube is by "Works By Design", a very cool design but probably too complex to ever be mass produced. Another video that had a big impact on me was "Unlucky In Locks" by Schuyler Towne. It's a good video in lock design and how humans have been trying to make a simple, unpickable lock for hundreds of years. I think the Kwikset SmartKey is the closest we have come to a mass produced lock perfection. It's cheap, mass produced. Basically unpickable for all but elite lockpickers, and it's rekeyable. The one feature your lock is missing. It's only fatal flaw is a brute force attack that mangles the internals but the lock still looks ok from the outside and may not be detected for a long time. Anyway loved the videos and good luck with your lock design.

An important aspect to it being preferable to redirect a potential trespasser to make an overt attack is that they are apparent if you are away during their entry and then you return before their exit. If you come home and there is a home invader inside, then the last thing you want to do is enter after them unaware of their presence.

Nice try, Tom Holland

very cool idea!

That modular design was super overengineered when an inline valve could have been used instead lol

Great Video once again.

You should be able to use food safe tubing and a peristaltic pump. I don’t think they cost that much for cheap ones

You really should reach out to Current Concept for a collab :) Excellent video btw :)

Now that's an underrated channel

How is any step of this easier than a bunch of peristaltic pumps?

Another way you can do it is instead of taking the cup to the drinks - take the drinks to the cup. Ie - increase the height of the drink bottles, and put a pipe from the drinks (output) to where the cup is. Thus getting rid of the motors .... Just put a lil door that closes instead - which could be controlled by a servo Then you can also dispense multiple at the same time - thus increasing dispense rate. - in your case, it just looked like singles. But say you do double - 2 of each drink (could stack on top of eachother or what not) But you can dispense twice as fast - or .... if you only start dispensing twice as fast after a few - then you can actually change the empty while the other is still busy/has liquid - so 1st empties, second empties and then both swapped - no downtime

wait all that just for it to die?

Lol, yep. I did a lot of testing, too, but evidently not the right kind of testing

in bio chem lab equipment. they often use peristaltic pump to move fluid without pump component contaminating the fluid culture. Since it move the fluid by contract the tubing from the outside. It move fluid at a predictable linear flow rate and has added benefit of a built in valve through tubing contraction. The pump cost about 5 bucks and you can get food safe tubing for around 6 bucks. Normally the downside is tubing get wear down from repeat contraction and require frequent replacement of the tubing. But since your use case is one time, longevity is not a concern. You might want to consider use a peristaltic pump instead for your next project.

The problem is that affordable peristaltic Pumps are very slow. It would take quite a lot of time for a drink of 0.4L

Very Cool and very overengineered

Quick question: Why not just pipe the dispensers up to one central cup-filling point?

great engineering and very well presented

Contact Bowley

While I enjoy engineering and picking, there’s a reason lock innovation has stalled out commercially. Locks are already to a point where destructive methods are faster and easier, I have bolt cutters and a Milwaukee m18 grinder so if I can’t do pick it quick it shall come off much faster anyway. I use mostly cheap master locks for this reason, bolt cutters are a far bigger threat than someone actually knowing how to pick a lock. Particularly for the rural area I’m in, a person is more likely to have a rifle in their truck then a bolt cutter and a few gun shots won’t draw any attention as people shooting in the backyard is normal.

total newbie here. My ideas are probably stupid, but I can think of two things: 1. can you use coils with different coefficients? I mean, one coil slightly harder than the order? So they will jump different heights when bumped. 2. instead of a coil pushing the pins down can you have a coil in the bottom part, cleverly mounted to pull the pins down? pull instead of push. A strong magnet pushing a special pin down? Just some ideas.

Your demonstration is absolutely great for describing the basics of bypassing those key pins

why not just put the bottles on a piece of hose and have vertical mounts for the bottles, then you can just take the bottle down flip it and take the hose off and swap bottles you could even add a ball valve

I freaking love this. Tricking me into learning something while showing off this cool build. Top notch stuff!

First principle, simplicity.

I wonder: couldnt you have used the dispensing cap thingys connected to some tubing and just pipe everything into one spot? And then just have servos actuate the caps...

are you one of those guys who looks 10 years younger than reality, major Jimmy from Donut Media vibes

Awww. Perfect project

Nice channel, always fun to see engineers with a sense of humour :D Reminds me of one guy making an "oils searching" robot for someones housewarming party. They had put an expensive natural oak floor in their house. And the robot was designed to randomly drive around and stop every few meters, drill a hole, and stick a flag in it - "There is no oil here!"

I think the best solution might be a two stage pumping system using peristaltic pumps to prime an internal reservoir that fills cups via gravity. That way you have fast turnover of drinks, low heat for electronics, and easy change of bottles. And maybe less expense for food grade parts.

Amazing video I can't wait to see what you make next.

I built myself a cocktail bot too. Although i went with the choice of pumps. My experience was that it is much faster and actually cheaper for most cases. Also less moving parts that are exposed- also i wasn't able to build a gantry :D Id love to discuss the thought process behind our both machines with you

We built a cocktail mixing machine 15 years ago at university. We used aquarium pumps to pump air into the top of liquor bottles. The higher pressure then moved the liquid through a thin hose to the cup. This way the liquids never come in contact with the pump and it's easy to control / dose.

I wonder if this would've worked to overcome the surface tension issue mentioned.

@@ibaron2716it would've. The air pressure being higher up top with force liquid to move which will then force the air at the bottom to move past the liquid. The only problem I could see with this is over pressurising the container.

*Who funds these experiments and huge time-sucks?*

a high paying job? probably one of those where if he left then the company would be screwed since no one else knows how anything works

6:05 Not enough gravity for the liquid, caused by partial vacuum in the bottle. I see no way for air to get back in the bottle after drooling out the liquid.

3:45 If done properly, current sensing will locate the limits easily, ie, Prusa printers.

3:20 *Original design: ETCH-A-SKETCH*

A scale under the cup might have helped with measuring/timing how long to keep the valves open. Sucks that it didn't last the night though!

You married a girl, right? If you bring a machine like that to a girl's wedding, you'll make her cry. Even I'm not that thick.

As an engineering student, I appreciate you taking the time to explain your decision-making process. Fair to many UA-cam makers neglect the importance of the decision-making process, especially in the early stages of a project. But I was wondering why you chose a gantry instead of a conveyor, screw, or turn table?

In a university project we faced a similar issue. We errent willing to spend the money on a food safe pump, so we went with an airpump and a filter. Instead of direftly pumping the liquid, we pumper air into the bottles, which then in turn would displace roughly the same volume of liquid. We had to cast some "universal corks" with tubes embedded to fit a multitude of bottles, and sparkling drinks created an issue. They would just build up pressure and drizzle, but we circumvented that by depressurising the system while the pump wasnt running. Overall it worked quite well. And it was a lot easier to clean, since the only parts where liquid actually was being pumped through was from the bottle to the nozzle, no solenoids or pumps came into contact with the liquid

Peristaltic pumps would have been so much easier, but a lot less entertaining. Cheers!

The dispensers usually are forced up then drop when the glass is taken away helping break the surface tension (mounting points are generally kinda flimsy and bend up with the applied force). Helps break the surface tension, although have seen air blocking it be an issue.

As soon as I heard how loud those stepper drivers were, I knew they were going to be a problem 😆